FPC-lasererotuskone

✧ Ominaisuudet

1. Varustettu 15 W 355 mn ultraviolettilaserilla, jolla on suuri huipputeho, vakaa teho ja alhainen vaimennus, ei tarvitse huolehtia tehon vaimennuksen vaikutuksesta leikkauslaatuun ja nopeuteen;

2. Integroi CTI:n erittäin tarkka skannaava galvanometri ja Yokogawa korkean tarkkuuden lineaarinen moottorialusta korkealla toimintatarkkuudella;

3. Ammattimainen leikkausohjelmisto voi tuoda suoraan CAD:n tuottaman DXF-grafiikan ja leikata syötegrafiikan mukaan tarkasti, jotta se leikkaa tarkasti ja tehokkaasti;

4. Optisen polun osan optimoidun suunnittelun jälkeen nopeus ja vaikutus voidaan optimoida samalla teholla, ja tehokas pölytiivis käsittely voidaan suorittaa samanaikaisesti, mikä voi tehokkaasti vähentää laitteiden sammutuksen huoltojaksoa;

5. Laitteessa on marmorinen tärinänvaimennusalusta, yleinen rakenne on vakaa ja kiinteä, ja integroitu suljettu rakenne takaa nopean, suuren tarkkuuden ja korkean tuoton tuotannon;

Ohjelmisto on yhteensopiva kaikentyyppisten toimintojen kanssa, yksinkertainen käyttö, helppo oppia ja ymmärtää, ja voit oppia perustoiminnot lyhyessä ajassa.

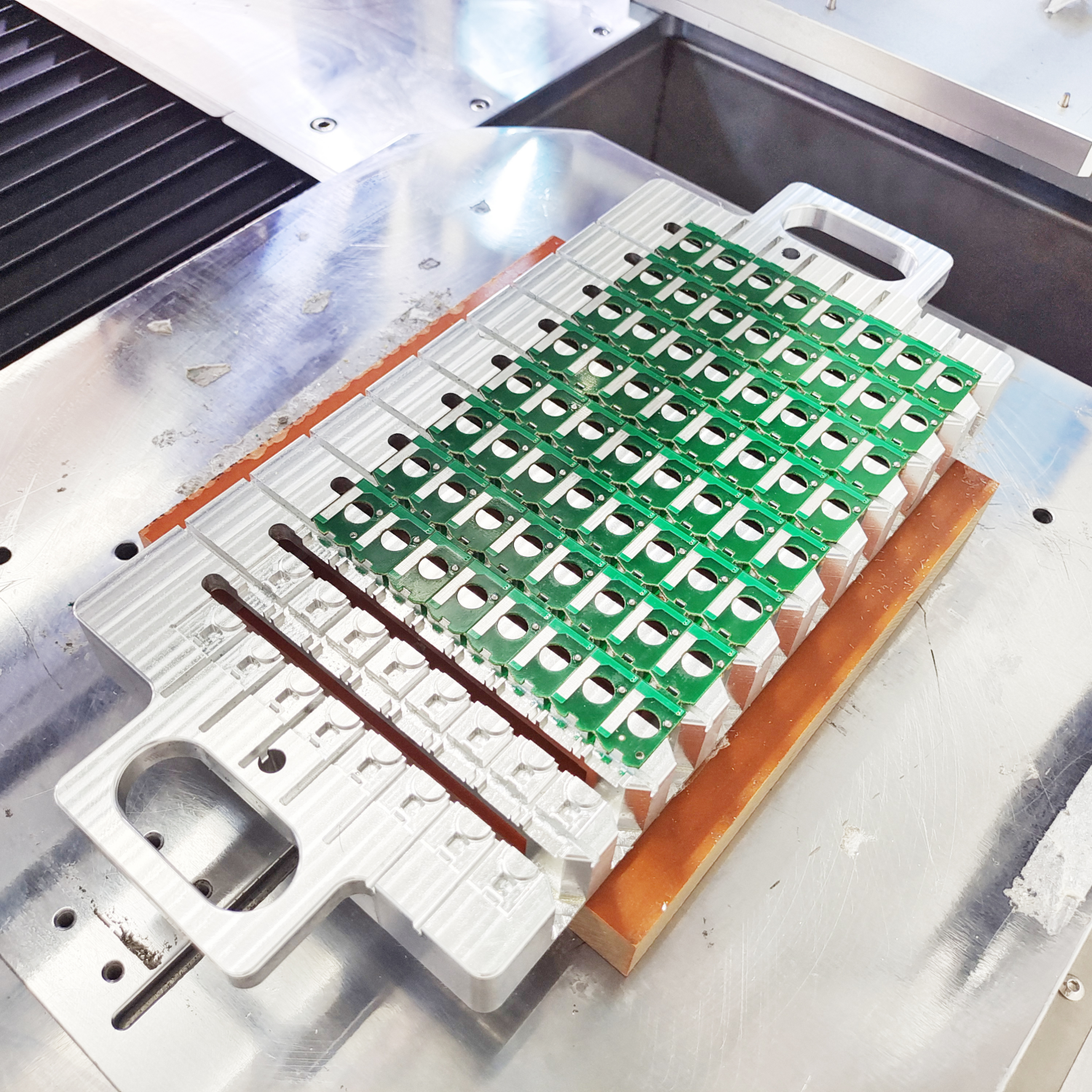

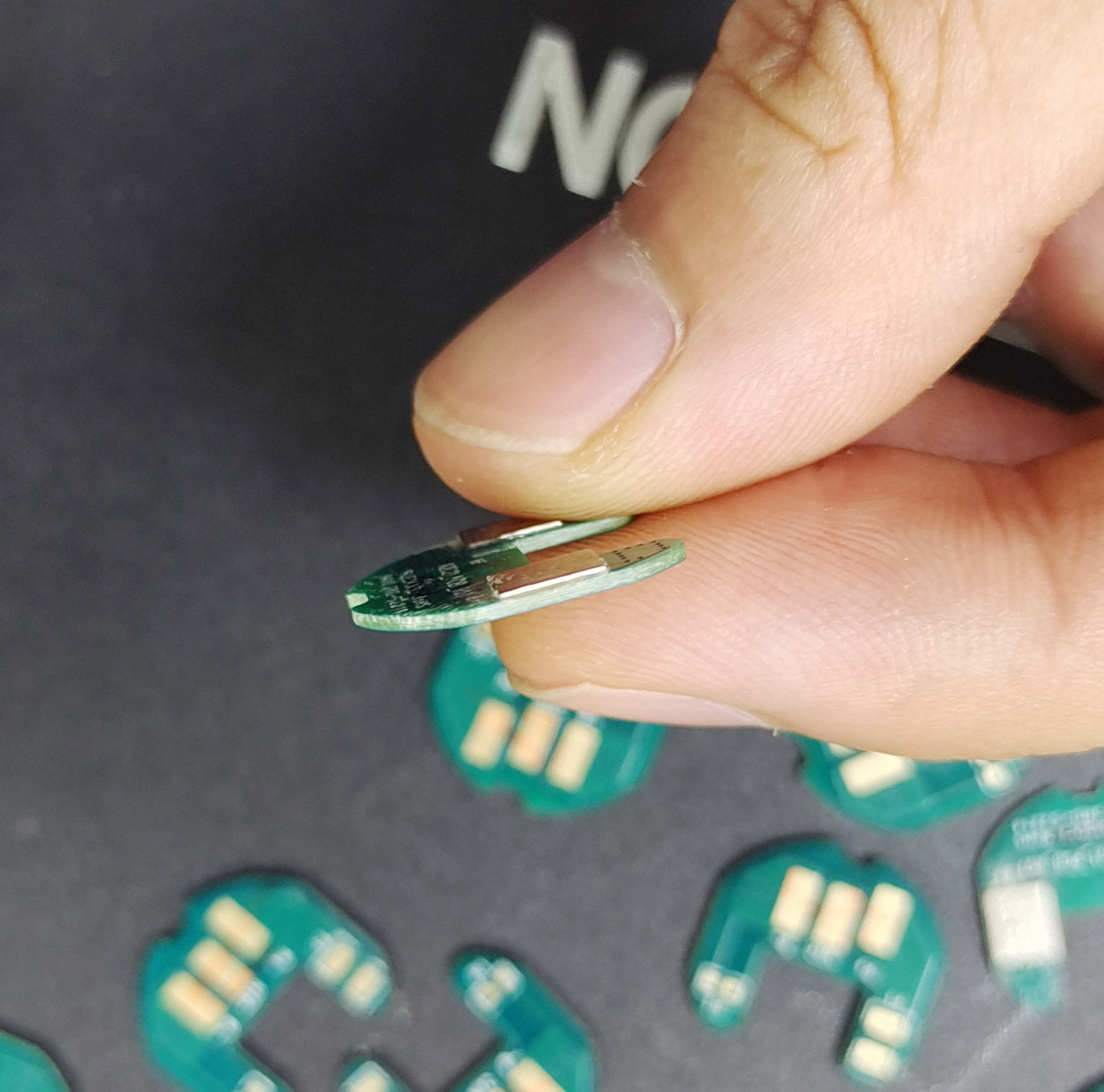

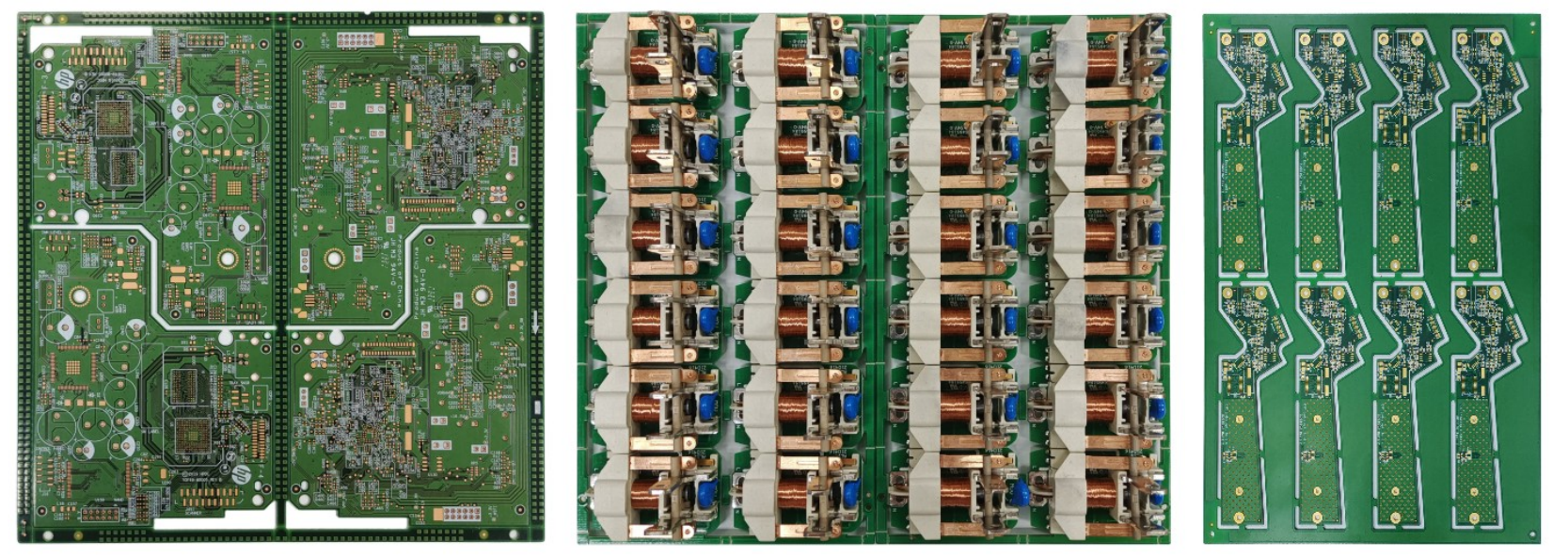

6.Sopii SMT-tuotantolinjalle, jota käytetään pääasiassa FPC:n, PCB:n, sormenjälkimoduulin, kameramoduulin, TYPE-C-liitännän ja kaikenlaisten tarkkojen PCB/FPC-levyjen leikkaamiseen 3C-teollisuuden tuotannossa.

✧ Tekninen parametri

| Leikkausalue | 350*350mm |

| Leikkaustuotteen enimmäiskoko | L350*L350*T1,0mm |

| Galvanometrin skannausalue | 42×42mm |

| Skannausnopeus | ≤5000mm/s |

| paikannustarkkuus) | ≤±3um |

| toista paikannustarkkuus) | ≤±2um |

| Alustan liikkumisnopeus | ≤1000mm/s |

| CCD-paikannustarkkuus | ±3um @1,3 miljoonaa pikseliä |

| Leikkuulinjan vähimmäisleveys | ≤30um |

| Suurin leikkauspaksuus | 1,0 mm (suositus) |

| Kattava leikkaustarkkuus | ≤±30um |

| Laitteen mitat | L1100*L1200*K1650mm |

| Laitteen paino | 1200kg |

| osa | malli | ominaisuudet |

| Laser | 15 W UV solid-state laser | Vakaa teho, alhainen vaimennus |

| Lineaarinen moottorialusta | Xiangjie-räätälöinti | Suuri nopeus ja vakaus |

| 4-akselinen liikeohjain | GTS-400-PV-VB-PCI | mittatilaustyönä |

| Teollinen PC | emolevy/i5-2400/4G/500G | Erillinen teollisuustietokone |

| Pyyhkäisevä galvanometri | CTI | Tuonti Amerikasta |

| Leikkausohjelmisto | Itsenäinen kehitys | Erikoisohjelmisto tarkkuusleikkaukseen, integroitu näön automaattinen paikannus |

| Marmorinen alusta | Marmori Zhangqiusta | Patenttisuunnittelu |

| Pölynkerääjä | 380V 3P 4KW | Räätälöity lasertarkkuusleikkaukseen |

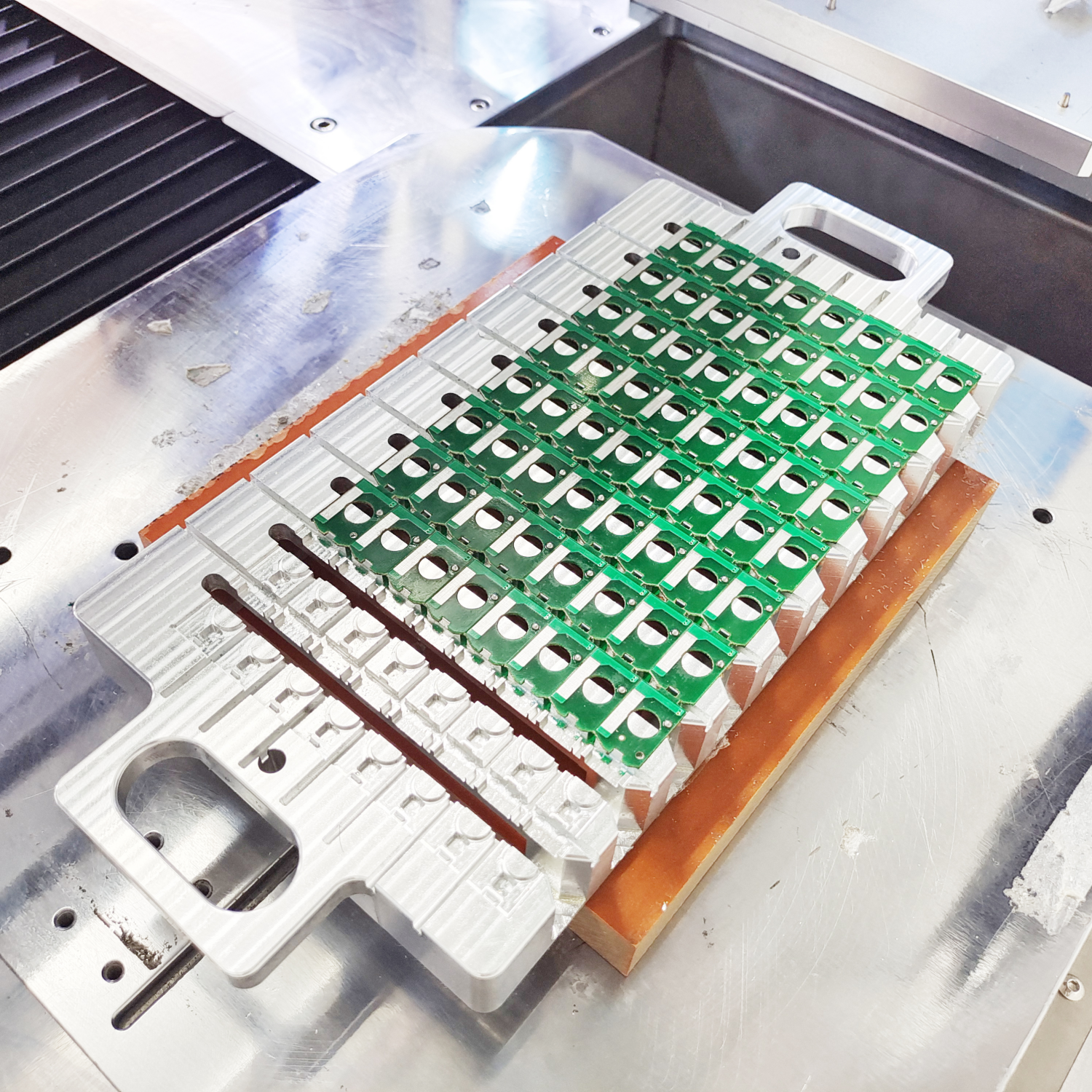

| kiinnitys | Räätälöity erikoiskiinnitys | Räätälöity asiakkaan tuotteiden mukaan |

| Jäähdytyslaite | / | Tarkka lämpötilan säätö |

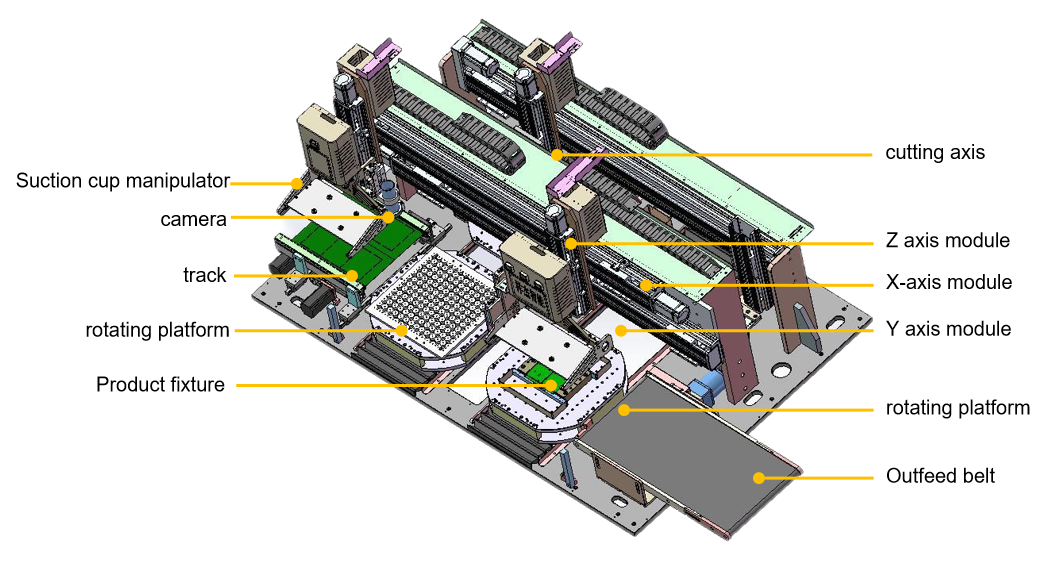

✧ Laitteiston esittely

-- Valinnainen käyttöjärjestelmä, Windows- ja Linux-käyttöjärjestelmien kaksoiskehitys, Huawein hyväksymä.Turvallisempaa ja avoimempaa

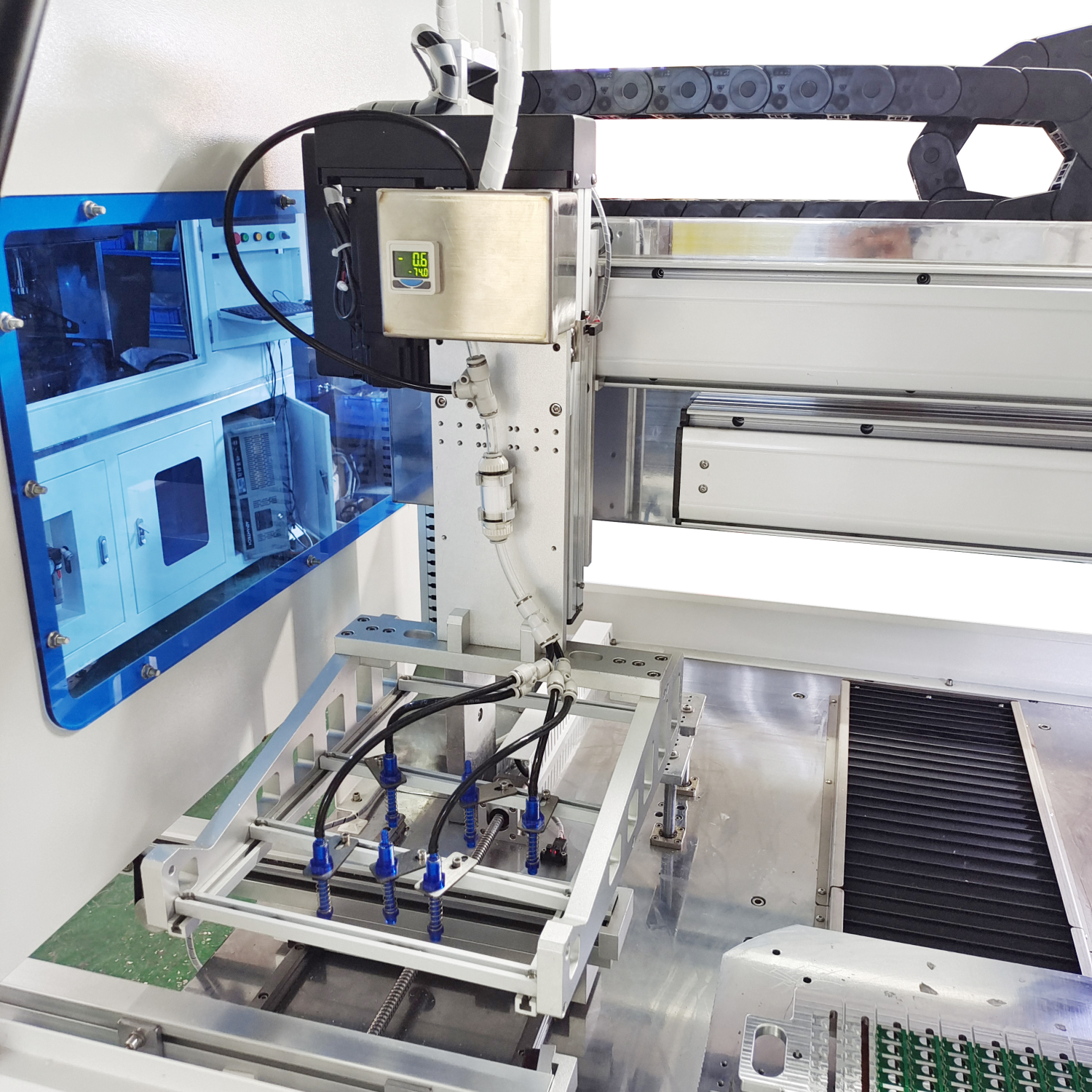

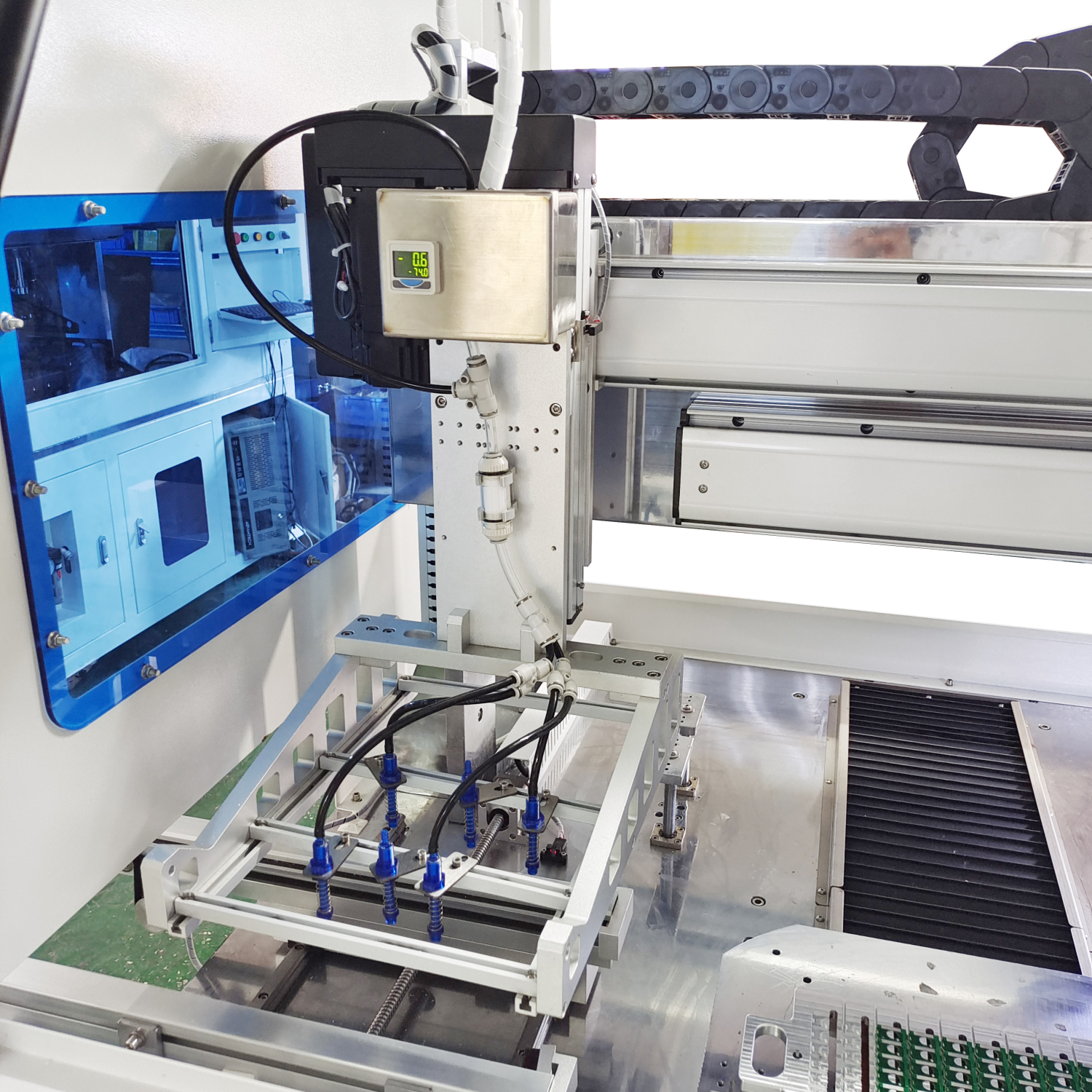

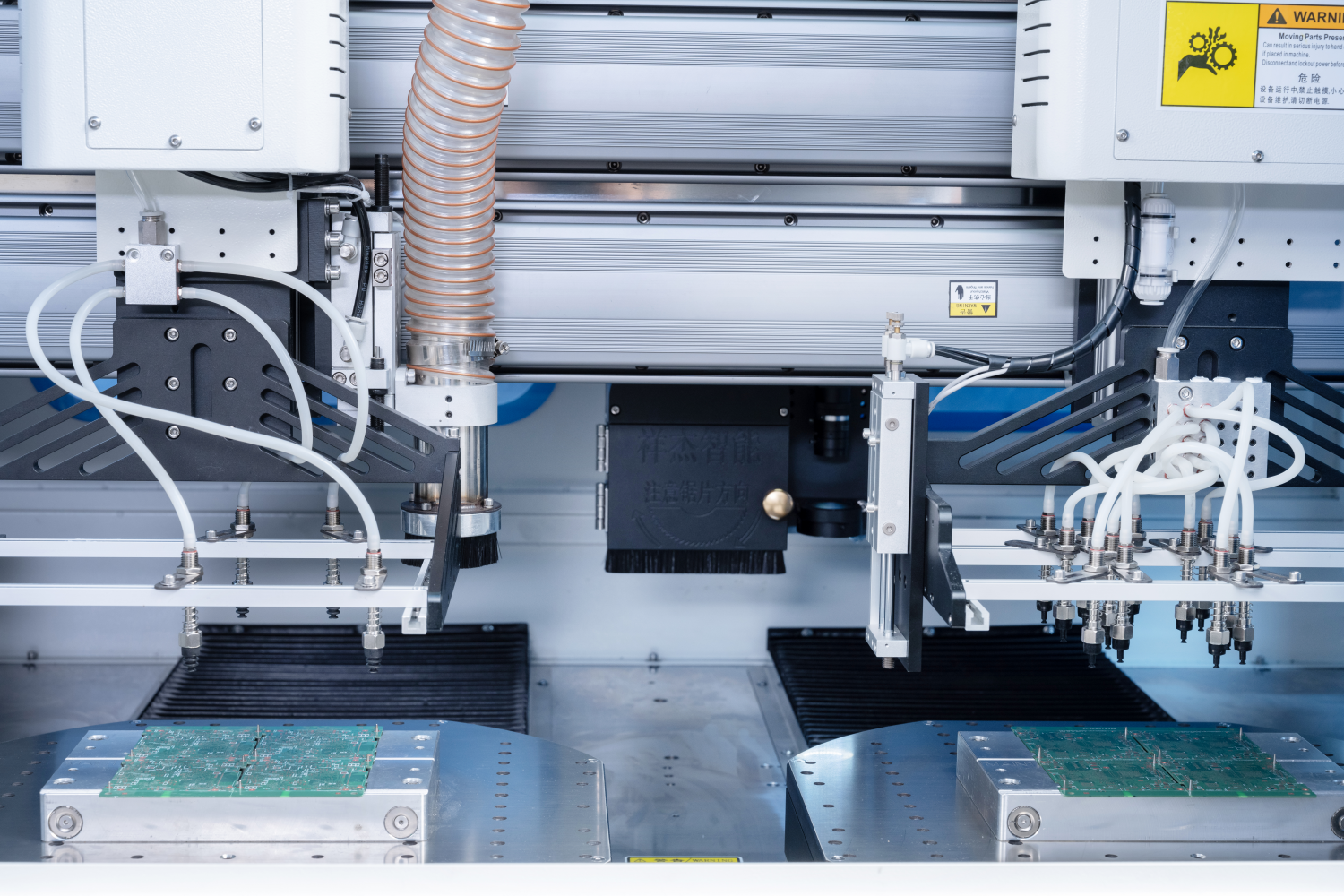

--Offline- ja online-kaksikäyttöinen kone, seuraa sisäänvirtausta, manipulaattori tarttuu automaattisesti saapuviin materiaaleihin ja järjestää levyn

-- Automaattinen CCD-näköskannaus, räätälöityjä tarkkuusvalaisimia leikkaustarkkuuden varmistamiseksi

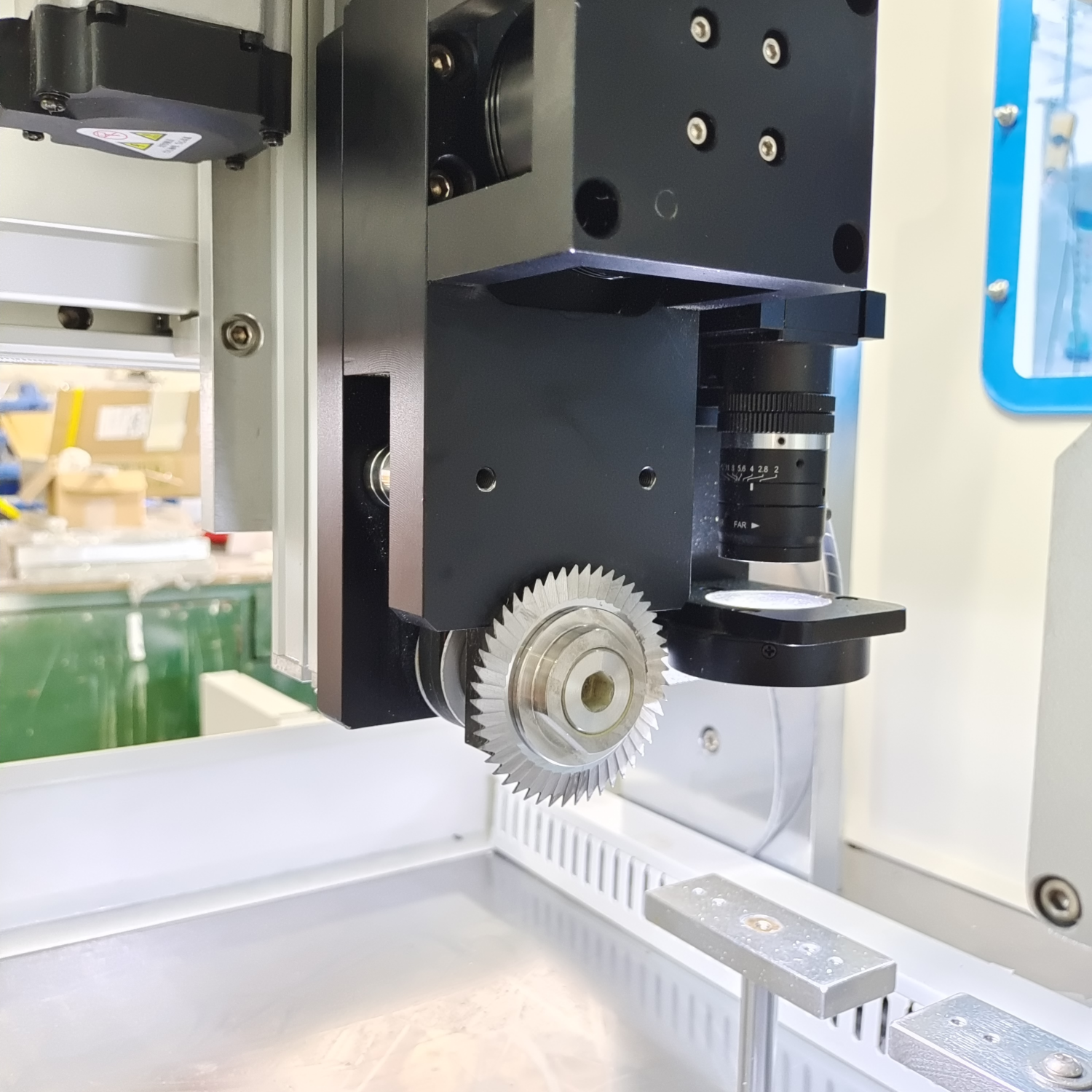

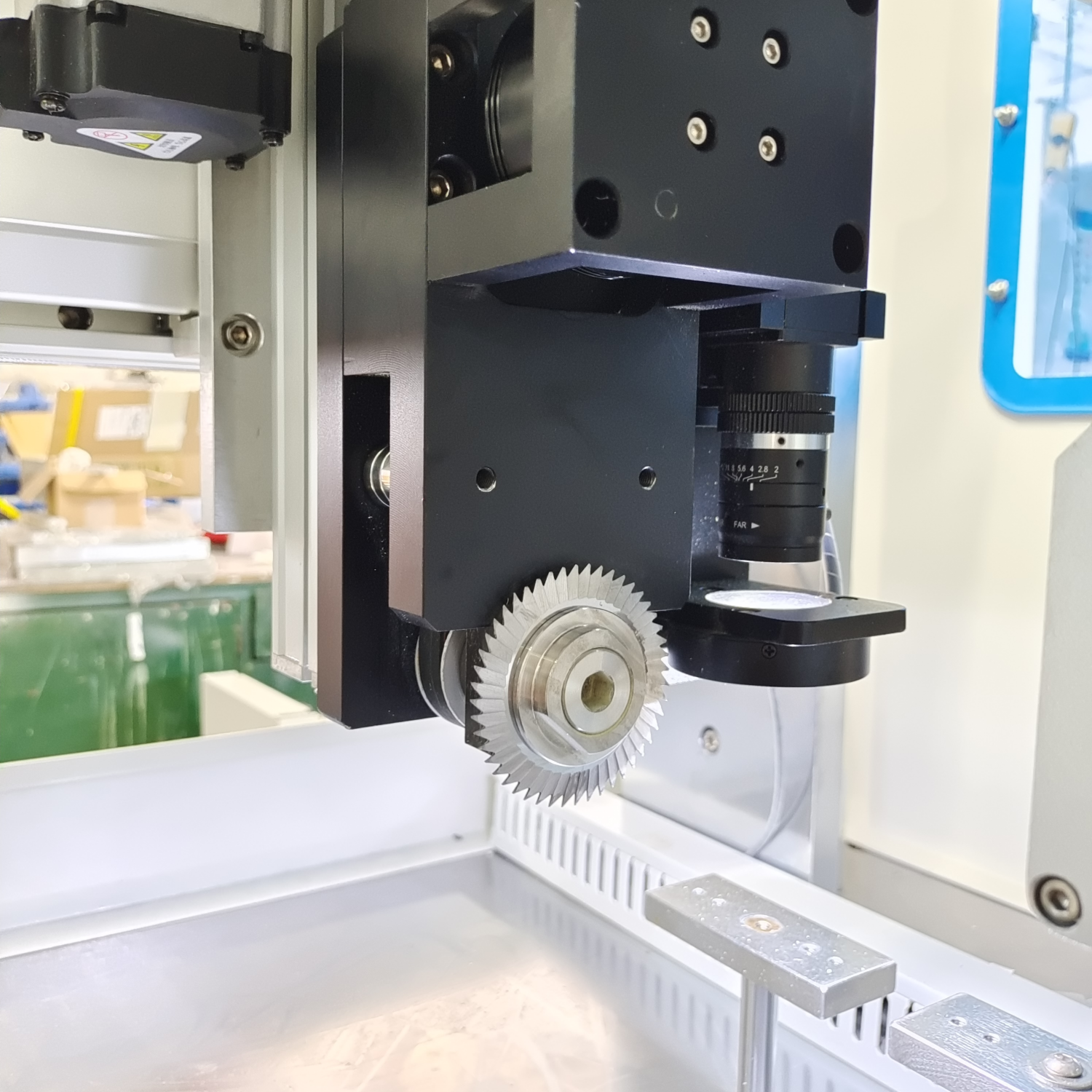

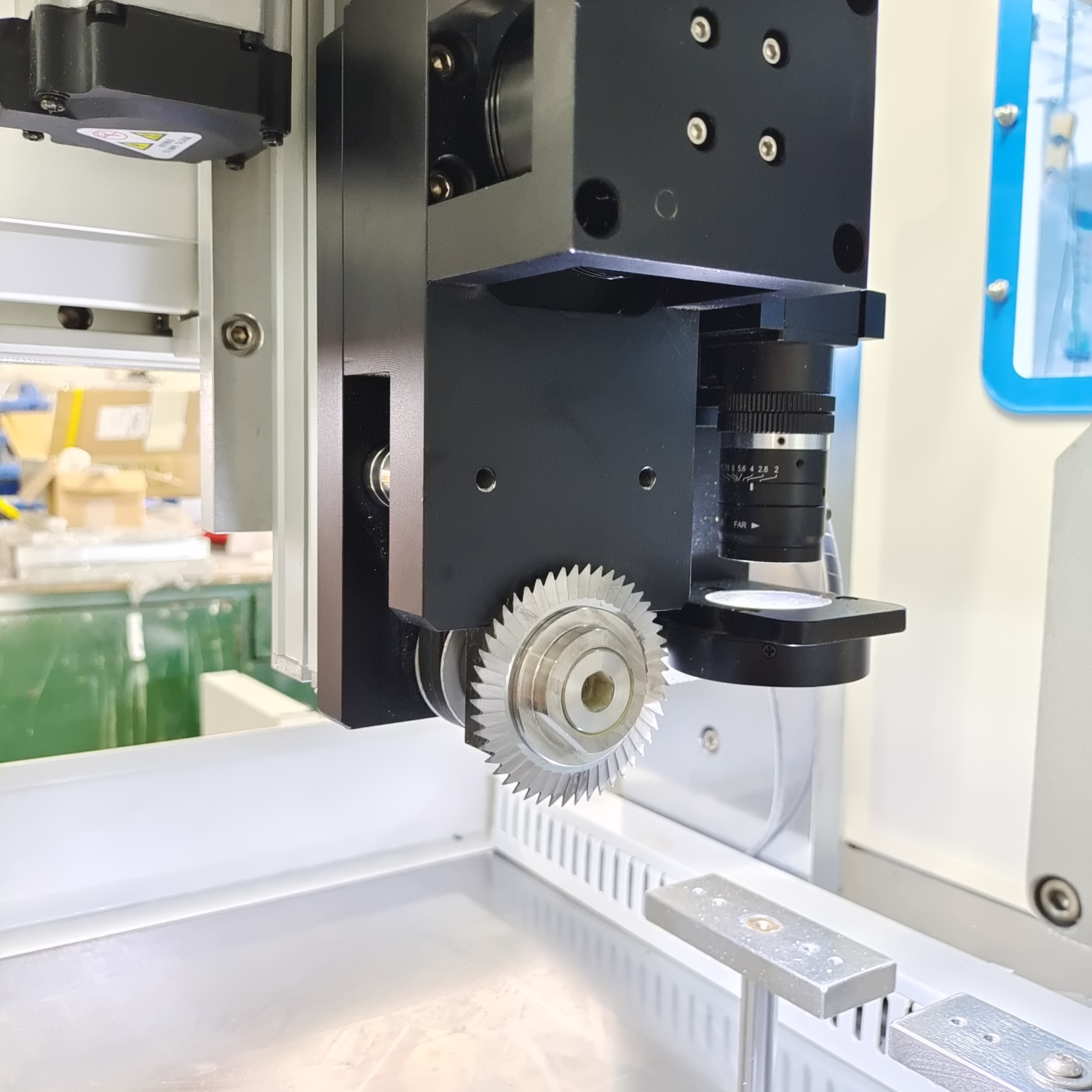

--Leikkaus sahanterillä, sopii kaikille V-CUT-levyille, eliminoi jatkuvan leikkaamisen ongelmat, nopeampi ja helpompi vaihtaa vaijerit

-- Leikkaus on piikkitön ja pinta sileä.Jaetun levyn jännitys on alle 300 μe.Ratkaise täysin tavallisen V-CUT-levyn jännityksen ongelma

--Varustettu pölynkerääjällä pölyn keräämiseksi synkronisesti leikkauksen aikana

✧ Merkkien paikannuskorjausjärjestelmä ja sahanterä

Se voi tehdä linjanvaihdosta ja jigin vaihdosta tiiviimmän ja tarkemman ja estää tehokkaasti levyn asettumisen paikoilleen verkkotuotannon aikana tai tuotteen leikkaamisen materiaalien sekoittumisen vuoksi.Yrityksestäsi lähtien's tuotteita voidaan käsitellä molemmilta puolilta, vakiomerkkipisteellä on vain yksi puoli, joten korjaustoimet ovat välttämättömiä, ja käytettävät merkkipisteet ovat yleensä epäsäännöllisiä muodoltaan ja muodoltaan;on helppo ilmoittaa virheistä tai offset-siirroista.Aiemman kokemuksen mukaan yrityksemme on parantanut huomattavasti tunnistuksen läpäisynopeutta ja kompensointitarkkuutta ottamalla käyttöön älykameran päivitysalgoritmin ja erityisen valonlähteen.

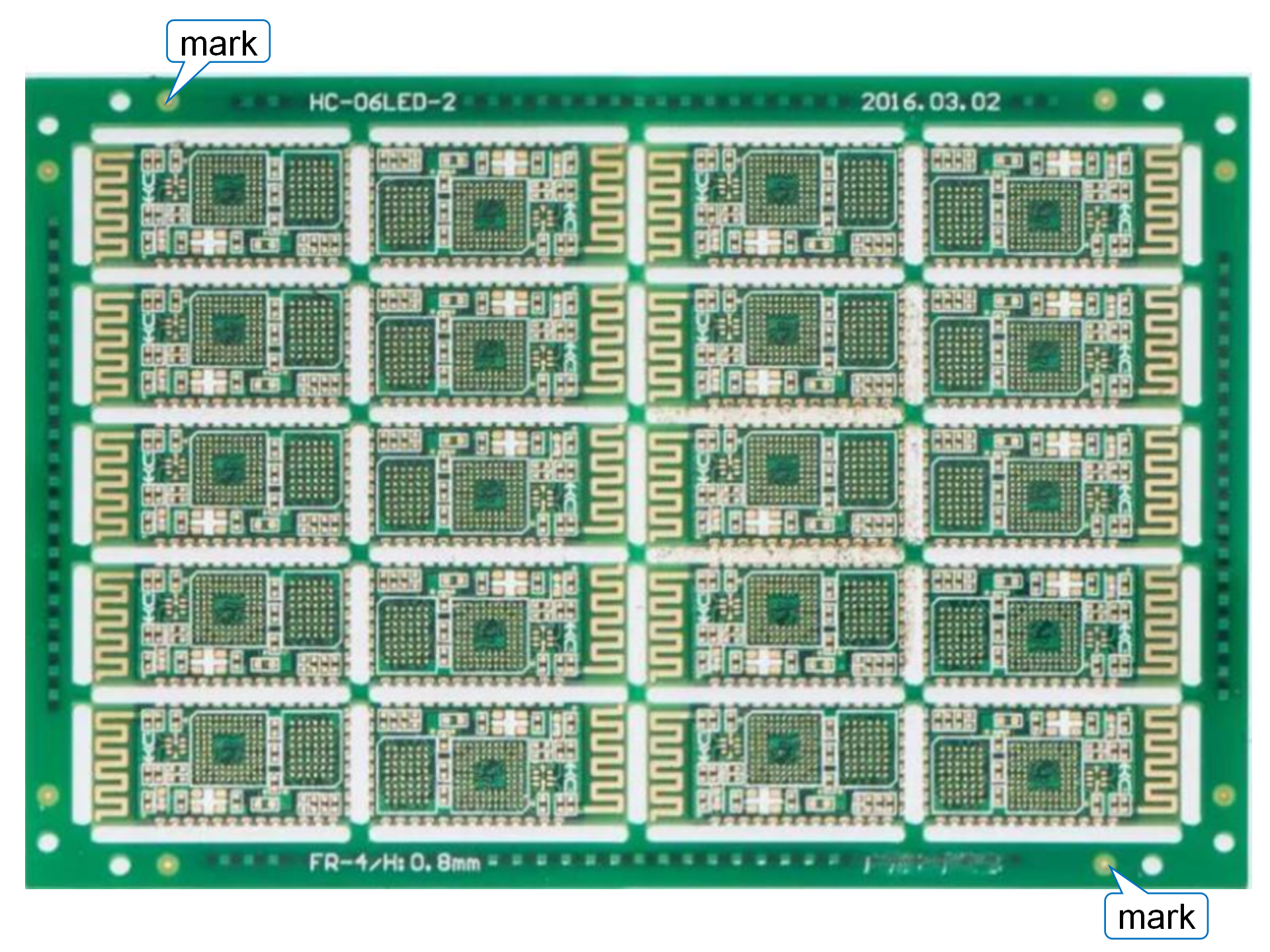

✧ Visuaalinen järjestelmä

Korkean pikselin värikamera ja suuri suurennoslinssi voivat auttaa ohjelman opetus- ja editointisimulaatiotoimintoja.Automaattinen MARK-paikannuskorjausjärjestelmä.

Merkintäpisteen korjausperiaate

Piirilevyn merkintäpisteen ja leikattavan liitoskohdan sijainti on fyysisesti kiinteä.Leikkauspolkua muokatessa, merkintäpisteen määrittämisen jälkeen muokattu leikkausrata sidotaan merkintäpisteen suhteelliseen sijaintiin.Kun piirilevy on esijännitetty, merkkipisteen sijainti muuttuu piirilevyn mukana.Kun kamera skannaa merkkikohtaa, se laskee automaattisesti siirtymän ja kompensoi sen sitten leikkausradalla.

✧ Tuotteen siirtoalusta

Kahden alustan modulaarisella servo-ohjausjärjestelmällä on erittäin korkea vakaus, ja leikkaustarkkuus voi saavuttaa±0,01 mm, joka voi täyttää erilaisia leikkaustarpeita ja varmistaa tuotannon laadun.

✧ Koneen rakenne

✧ Käytä

Sekä V-urat että pisteliitännät sisältävien piirilevyjen leikkaamiseen

✧ Pakkaus ja toimitus

Puinen pakkaus

Puinen pakkaus

✧ Kuljetustie

→ Lentoteitse: näytteille ja pienille pakkauksille, kansainvälinen pikakuljetus, kuten DHL, UPS, EMS...

→ Meritse: suurelle paketille ja määrälle;

→ Muut tavat asiakkaan pyynnöstä.

Toimitusaika:

→ 35 päivän sisällä.

✧ Yrityksen tiedot

Vuonna 2008 perustettu Xiangjie Technology, jonka pääkonttori sijaitsee Dongguanissa, on maailman tuotantopääkaupunki.Se on piirilevyjen leikkaus- ja juotosratkaisuihin keskittyvä toimittaja, joka on sitoutunut tarjoamaan standardoituja korkealaatuisia laitteita ja räätälöityjä palveluita maailmanlaajuisille käyttäjille.Yli kymmenen vuoden innovaation ja kehityksen jälkeen, erityisesti piirilevyjen leikkaamisen alalla, Xiangjie Technologysta on tullut johtava SMT-oheislaitteiden valmistaja Kiinassa ja maailmankuulu valmistaja.Vahvan innovatiivisen T&K-tiimin ja vahvan myynti- ja huoltopalvelukyvyn ansiosta se on palvellut yli 30 maassa ja alueella.

✧ Näyttely

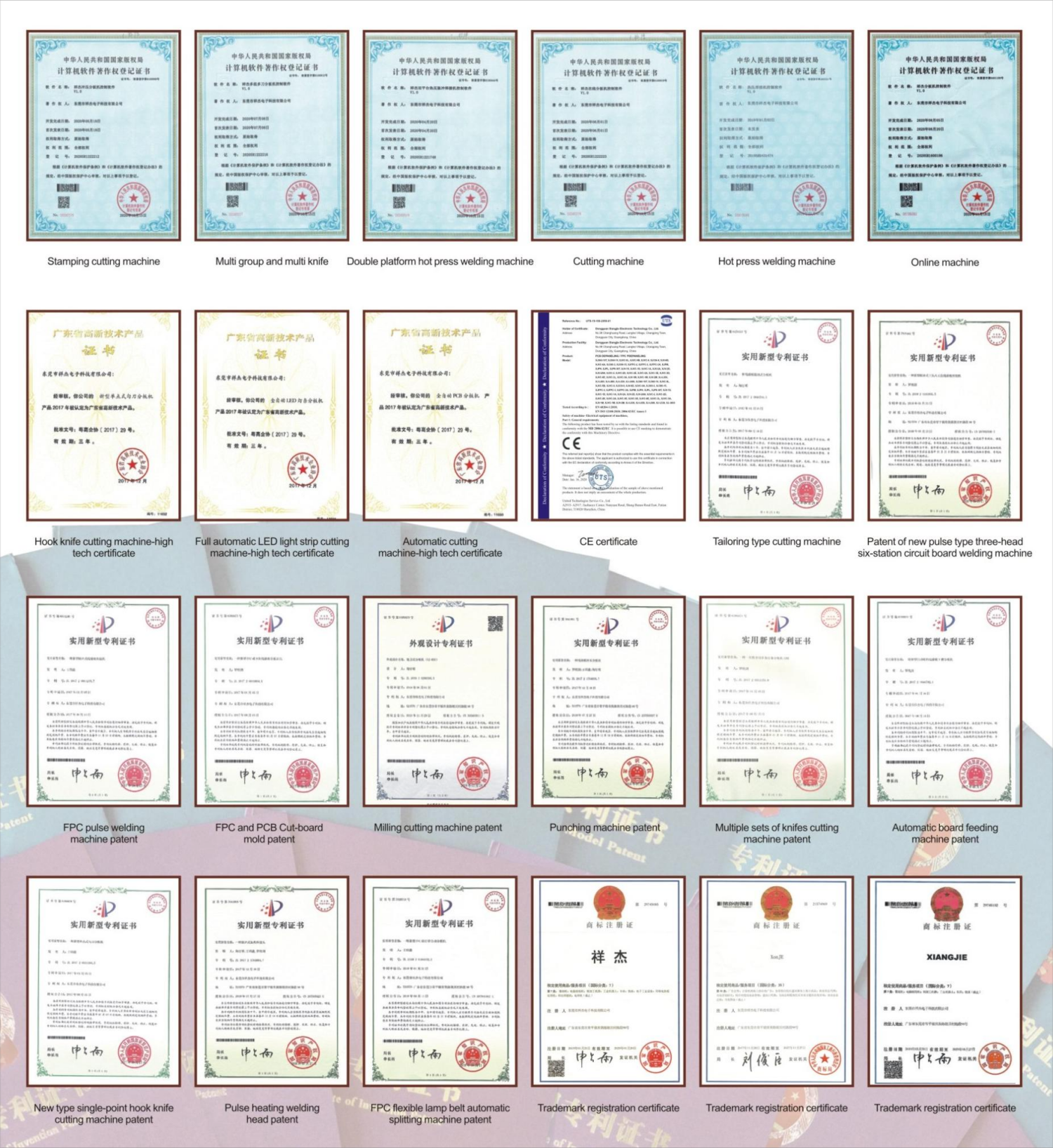

✧ Tavaramerkki ja patentti

Xiangjie Technology on saanut useita keksintöpatentteja, yli 30 käytännön patenttia ja erilaisia korkean teknologian tuotteita.

✧ UKK

K: Mitä voimme tehdä sinulle?

V: Ammattimainen SMT-oheislaitteiden toimittaja;Yli kymmenen vuoden kypsä alan kokemus

K: Oletko kauppayritys tai valmistaja?

V: Olemme valmistaja, jolla on täydelliset käsittelylaitteet

K: Mikä on toimituspäiväsi?

V: Noin 35 päivää maksun vastaanottamisesta.

K: Mitkä ovat maksuehtosi?

V: 100% saldo ennen lähetystä.

K: Mitkä ovat pääasiakkaasi?

V: PCB-kokoonpanon valmistaja, SMT-laitteiden valmistaja, valonauhan valmistaja jne.

K: Miksi valita sinut?

V: Johtava SMT-toimittaja Kiinassa;

Kaupan vakuutus USD 560 000+;Ammattimainen myynnin jälkeinen palveluryhmä.