Muovinen kuumaniitauskone

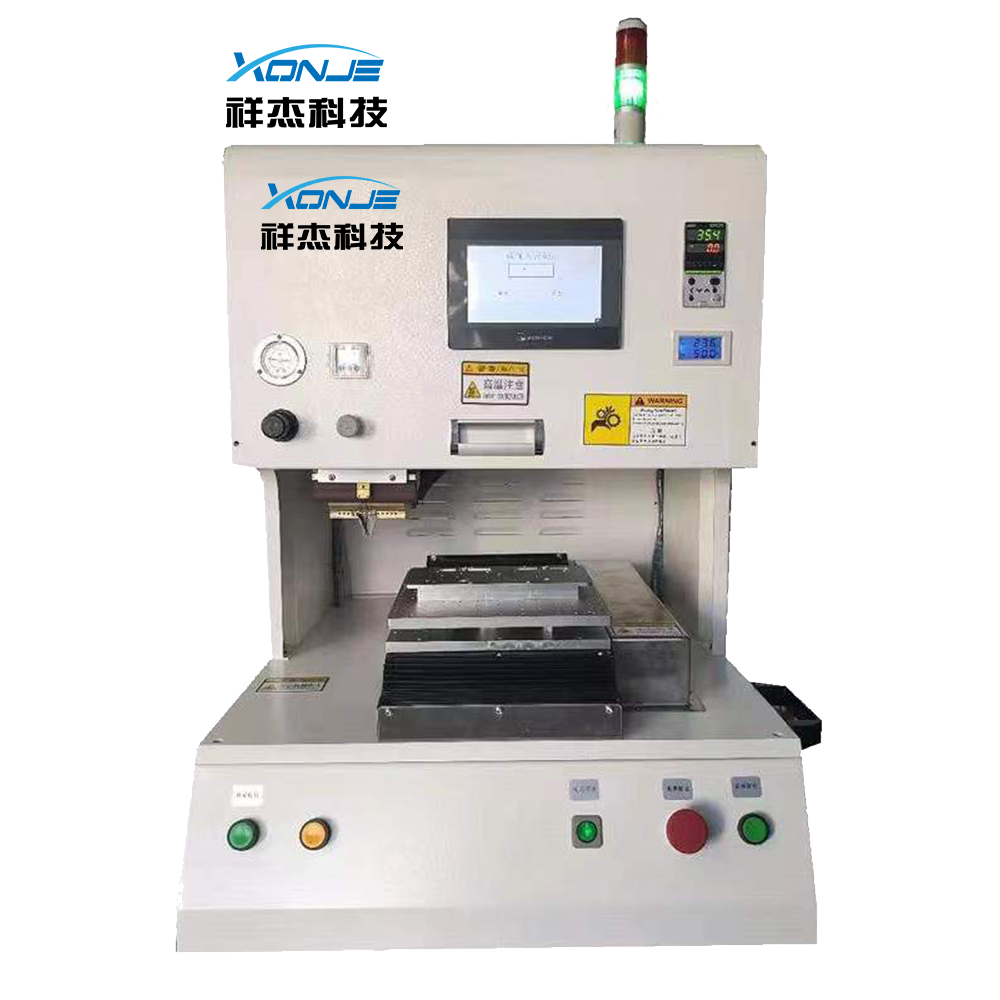

✧ Ominaisuudet

1. Eri tuotteiden mukaan lämmitysnopeutta voidaan säätää;

2. Erikoismateriaalien hitsausliitokset varmistamaan tuotteen tasaisen jännityksen;

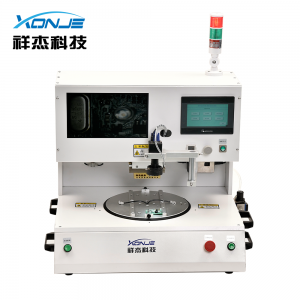

3. Varustettu tyhjiötoiminnolla, on helpompi säätää kohdistusta;

4. Lämpötila on numeerisesti ohjattu, selkeä ja tarkka, kosketusnäytön toiminta, kiinalainen ja englanninkielinen näyttöliittymä, PLC-ohjaus, yksinkertainen käyttö;

5. Varustettu digitaalisella painemittarilla, painealue voidaan esiasettaa, käytetään SMC-tarkkuusohjainkisylinteriä, puristustarkkuus on korkea ja tuote, jonka juotosliitosväli on 0,5 mm, voidaan hitsata;

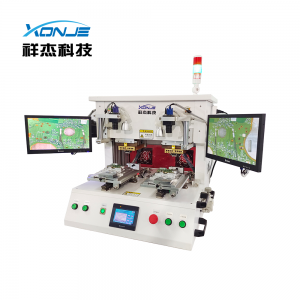

6. Automaattinen pääsy alustalle, kätevä operaattoreille työskennellä nopeasti;

7. Varustettu teräväpiirtoisella CCD-suurennuksella ja teräväpiirtonäytön kohdistuksen tarkastuksella viallisten tuotteiden estämiseksi ja tuotteen hitsaus on täysin oikea;

8. Soveltuu erilaisiin suuritiheyksisiin TAB-, TCP-puristus- ja FPC-, FFC-, TFT- ja PCB-juotepuristamiseen.

*Juoteliitäntä FPC:n ja PCB:n ja liittimien välillä.

*ACF:n ja PCB:n välinen liitäntä ja liittimet.

*Liitä TAB:n ja PCB:n ja liittimien välillä.

*TFT:n ja PCB:n välinen liitäntä ja liittimet.

* Juotosliitäntä FFC:n (joustava litteä kaapeli) ja piirilevyn ja liittimien välillä.

*Juoteliitäntä seeprapaperin ja piirilevyn ja liittimen välillä.

*Juoteliitäntä erittäin hienon koaksiaalikaapelin ja piirilevyn ja liittimen välillä.

*Emaloitujen johtojen, kuten kiintolevyjen, juotosliitännät.vastukset, kondensaattorit, kelat, muuntajat, IC-kortit jne.

*Juoteliitäntä akun napakappaleen ja piirilevyn ja liittimen välillä.

*Pienten moottoreiden käämiliitäntöjen juotos.Hartsi lämpöpuristusliitos releille, tulostimille, laseille jne.

✧ Tekninen parametri

| Malli | XJPM-2A |

| Paikannusteline | 1 sarja |

| Työalue | 100*130mm |

| Käytä jännitettä | 220VAC 2,5KW |

| työpaine | 0,5-0,7 MPA |

| Koneen paino | 100kg |

| P*L*K | 650 * 650 * 750 mm |

| Lämmitysmenetelmä | Jatkuva lämpötilalämmitys |

| Lämpötilan säätö | Huonelämpötila ~350°C voidaan asettaa |

| Lämpötilan säädön tarkkuus | ±2°C |

✧ Pakkaus ja toimitus

Puinen pakkaus

Puinen pakkaus

✧ Kuljetustie

→ Lentoteitse: näytteille ja pienille pakkauksille, kansainvälinen pikakuljetus, kuten DHL, UPS, EMS...

→ Meritse: suurelle paketille ja määrälle;

→ Muut tavat asiakkaan pyynnöstä.

Toimitusaika:

→ 35 päivän sisällä.

✧ Yrityksen tiedot

Vuonna 2008 perustettu Xiangjie Technology, jonka pääkonttori sijaitsee Dongguanissa, on maailman tuotantopääkaupunki.Se on piirilevyjen leikkaus- ja juotosratkaisuihin keskittyvä toimittaja, joka on sitoutunut tarjoamaan standardoituja korkealaatuisia laitteita ja räätälöityjä palveluita maailmanlaajuisille käyttäjille.Yli kymmenen vuoden innovaation ja kehityksen jälkeen, erityisesti piirilevyjen leikkaamisen alalla, Xiangjie Technologysta on tullut johtava SMT-oheislaitteiden valmistaja Kiinassa ja maailmankuulu valmistaja.Vahvan innovatiivisen T&K-tiimin ja vahvan myynti- ja huoltopalvelukyvyn ansiosta se on palvellut yli 30 maassa ja alueella.

✧ Näyttely

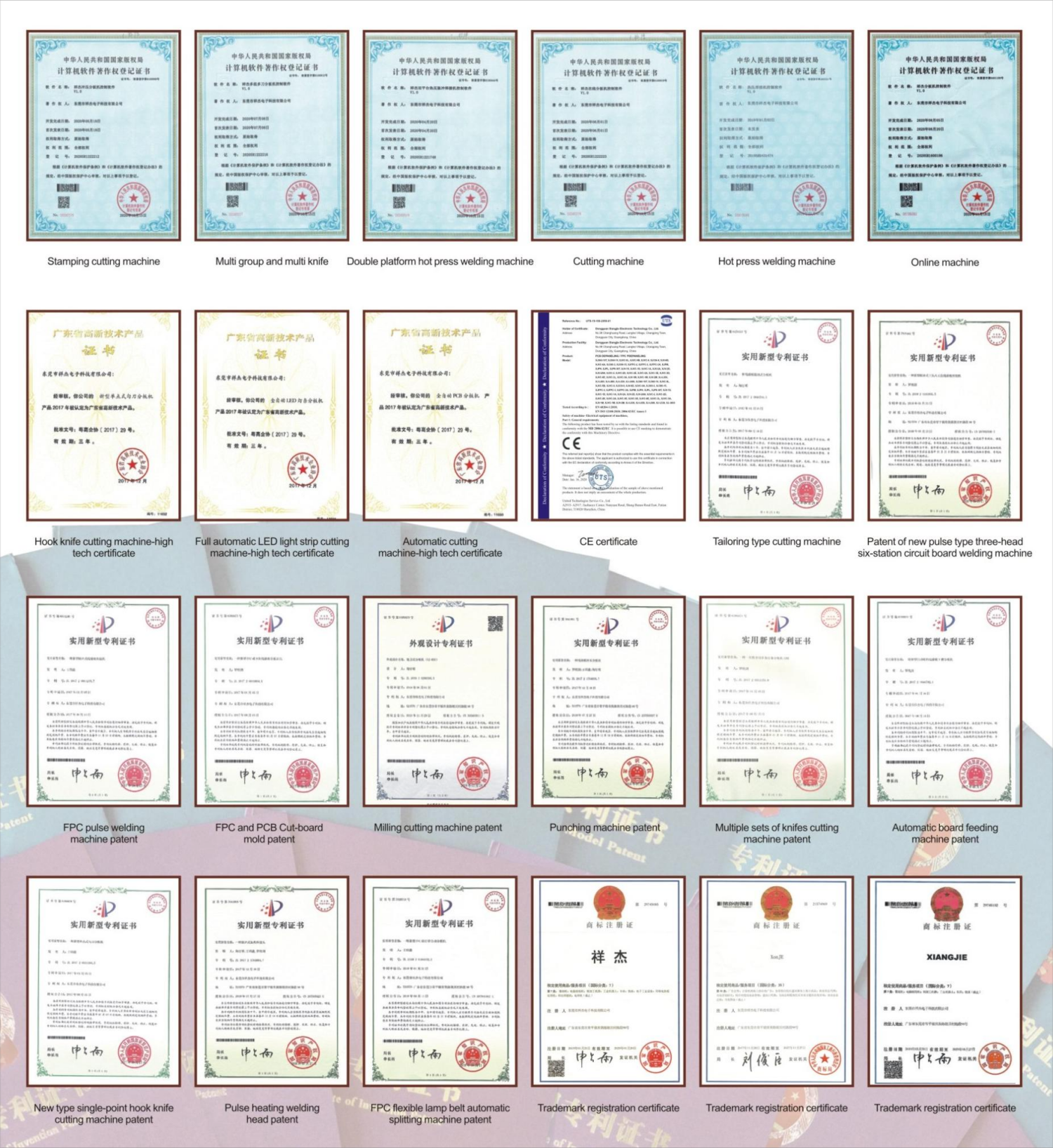

✧ Tavaramerkki ja patentti

Xiangjie Technology on saanut useita keksintöpatentteja, yli 30 käytännön patenttia ja erilaisia korkean teknologian tuotteita.

✧ UKK

✧ Miksi valita meidät

Erikoistunut PCB-leikkuukonelaitteiden ja piirilevyjen kuumapuristusjuotoskonelaitteiden tuotantoon,

Olemme sitoutuneet tuottamaan asiakkaita tyydyttäviä tuotteita, räätälöimään tieteellisiä, järkeviä ja tehokkaita ratkaisuja sekä auttamaan yrityksiä parantamaan tuotantolinjan tehokkuutta ja laatua.