Jännitysmittari

✧ Ominaisuudet

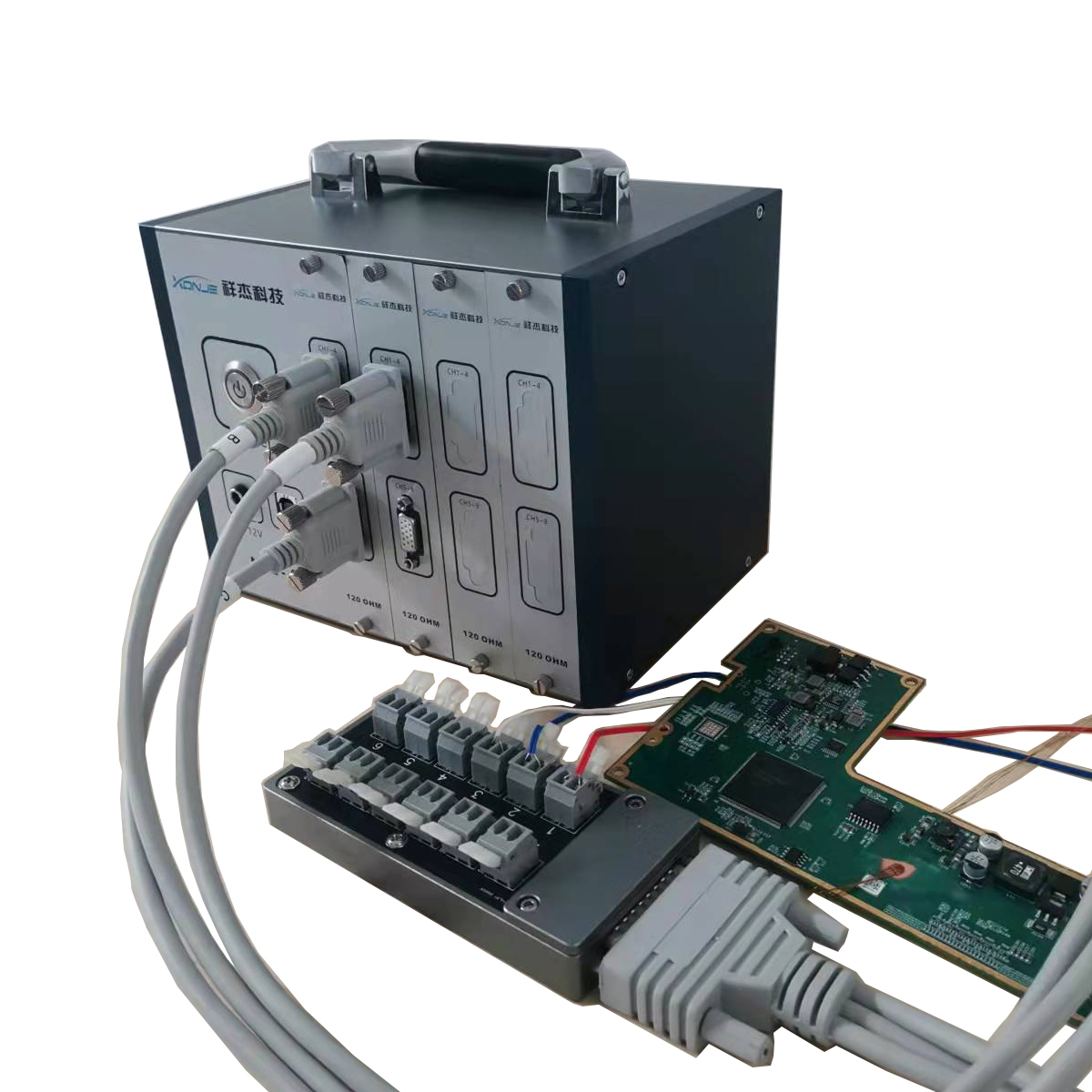

1. Se käyttää modulaarista lähestymistapaa, jokaisessa jännitysmoduulissa on 8/4 hankintakanavaa, jota ei voi laajentaa.

2. USB-liitännän kautta se voi tallentaa pitkäaikaista tietoa isännän kiintolevylle.

3. Kerätty signaali on 120/350 ohmin jännitysmittari (käytetään eri moduuleita).

4. Suurin näytteenottotaajuus on 10 KHz (8/4 kanavaa näytteistetään samanaikaisesti).

5. Käyttövalikko on valintaikkunan muodossa, jossa on kiina/englanti käyttöliittymä, joka on yksinkertainen ja nopea.

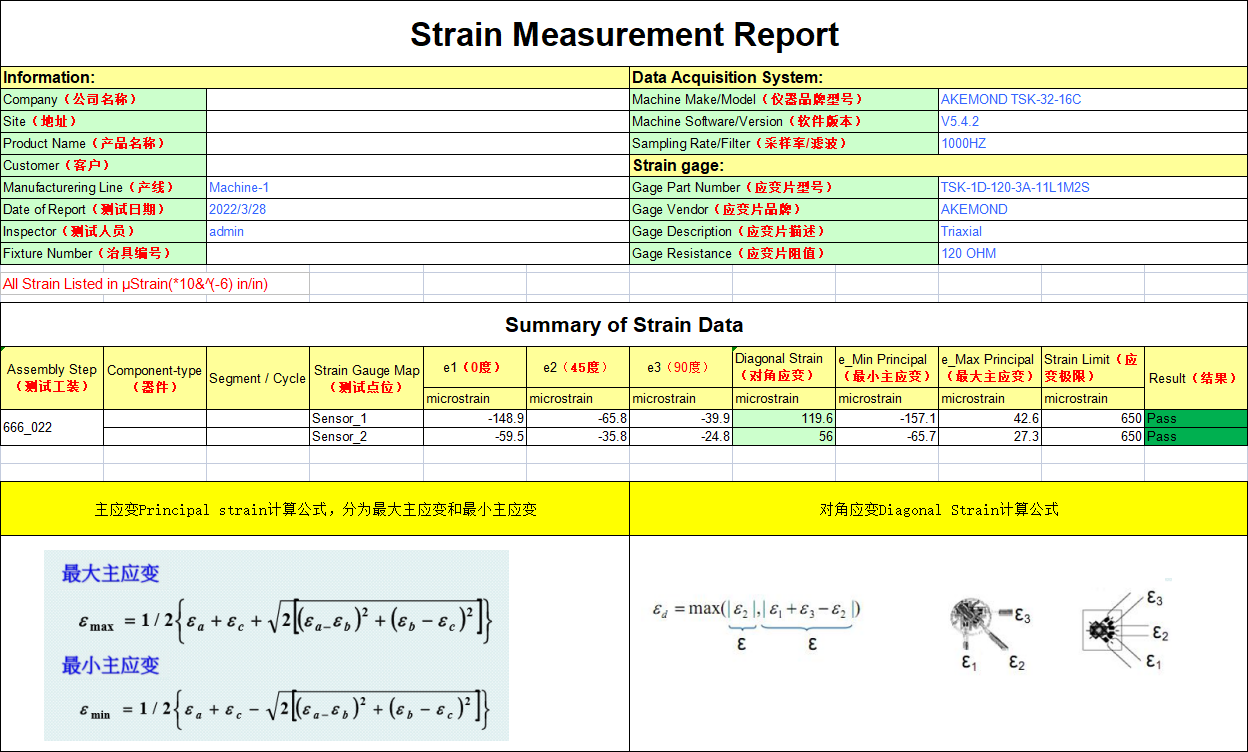

6. Yhdistämällä kansainvälisen venymämittarin testistandardin Intel-standardin ja IPC-9704-standardin, yhden näppäimen automaattisen raportin luomisen ja arvioinnin 'hyväksytty' tai "epäonnistui".

✧ Tekninen parametri

| Kanavien määrä per moduuli | 8/4 analogista tulokanavaa |

| Suurin näytteenottotaajuus | 80KS/s/runko |

| Näytteenottotila | Monikanavainen samanaikainen näytteenotto |

| ADC resoluutio | 24 bittiä |

| Tukee venymämittarin anturin resistanssiarvoa | Tukee 120Ω |

| Tukee Wheatstonen siltatyyppiä | 1/4 silta |

| Muunnostarkkuus | 3.5062nV/V/LSB |

| Tarkkuuden vahvistusvirhe | 0,02 % (kalibroitu, tavanomaiset mittausolosuhteet 25 ℃, ± 5 ℃) |

| Täysi valikoima | ±29,4 mV/V (+62500uE/-55500uE) |

| Ylijännitesuoja napojen välillä | ±30V |

| Vakaus | 6 ppm/℃ (Gain drift 6 ppm/℃) |

| Rungon käyttöliittymätyyppi | USB2.0 nopea sisääntulo |

| Virtalähde | 11-30 VDC, 220 VAC |

| Työskentelylämpötila | -40 ℃ ~ 70 ℃, käyttökosteus: 10 % ~ 90 % RH, ei kondensoituva |

| Säilytyslämpötila | -40 ℃ ~ 85 ℃, säilytyskosteus: 5 % ~ 90 % RH, ei kondensoituva |

| Suojaustaso | IP40 |

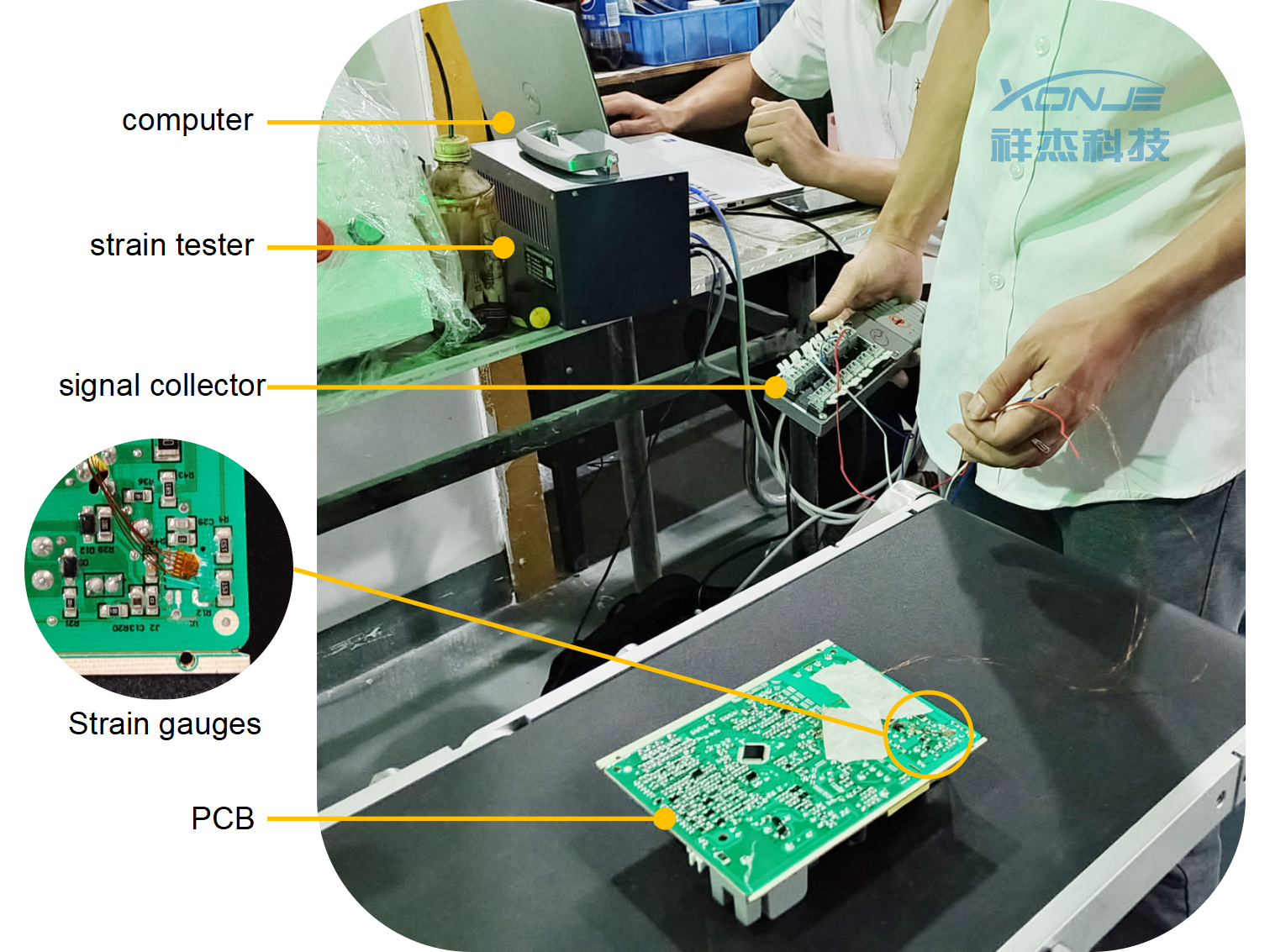

✧ Venymätestausprosessi

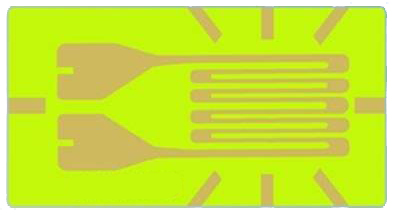

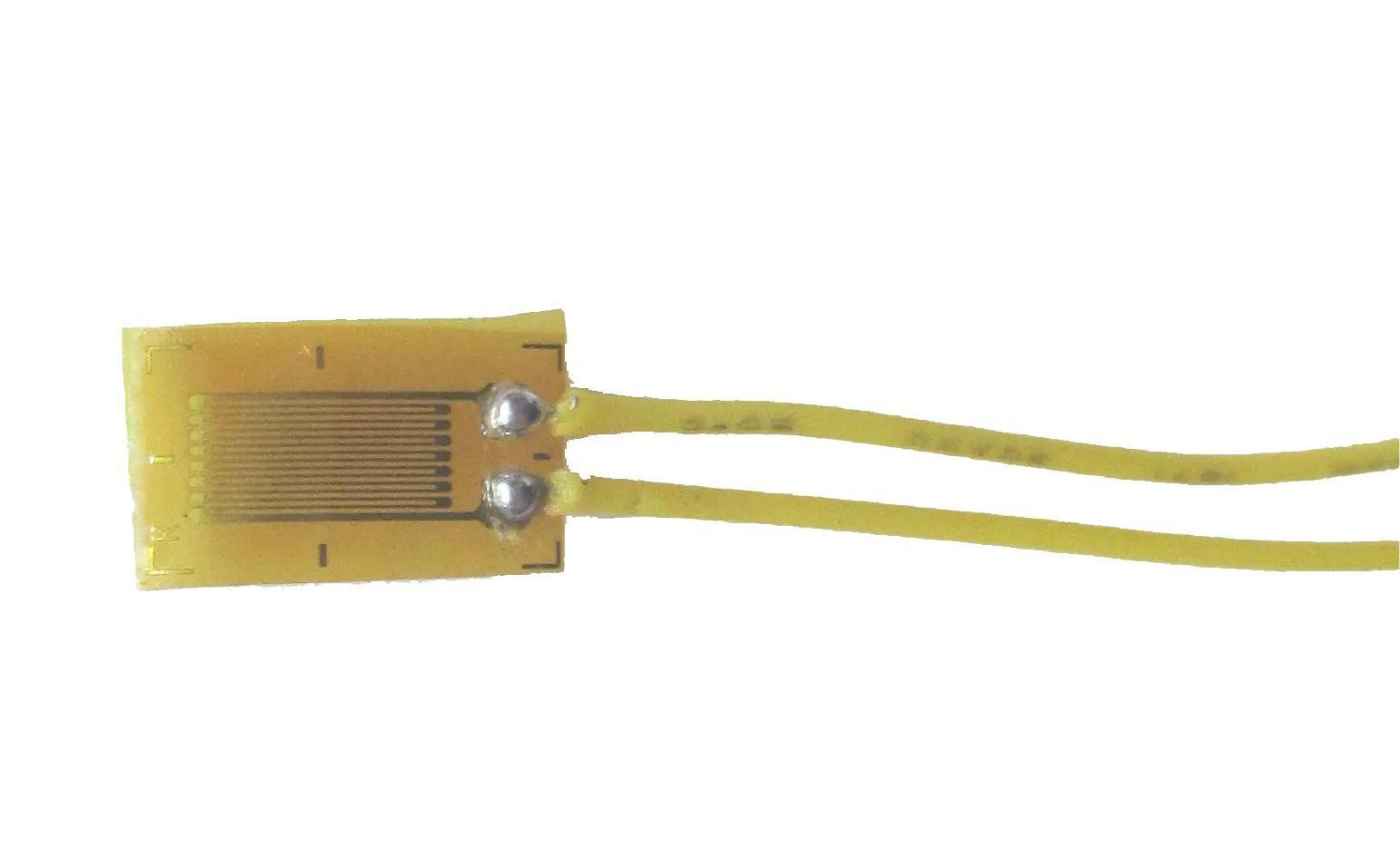

✧ Kulutusosien venymämittarit

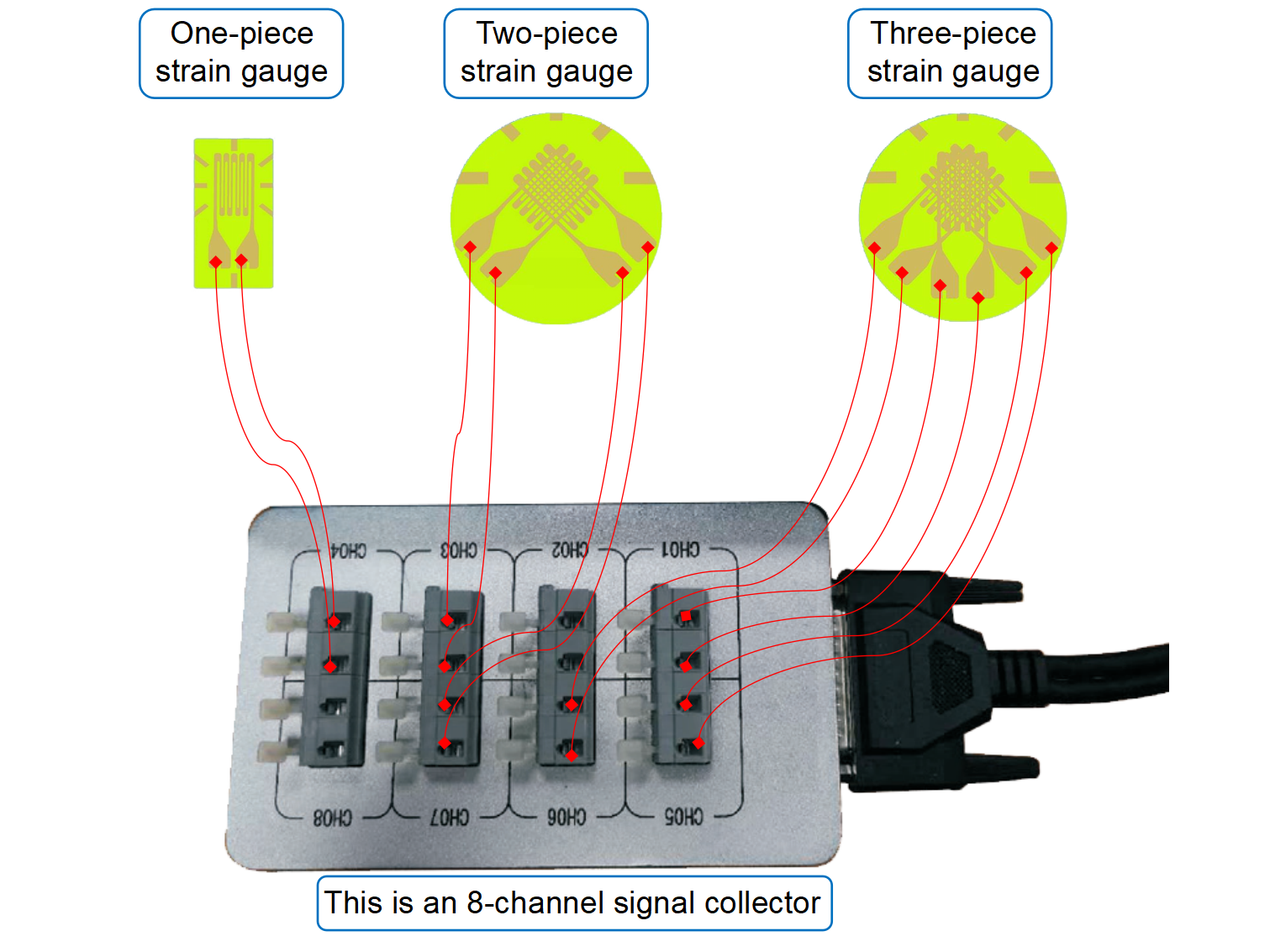

Yksiosainen venymämittari

(Todellinen kuva)

Kaksiosainen venymämittari

Kolmiosainen venymämittari

✧ Venymäanturien ja signaalinkeräinten liitäntä

✧ Venymätestiraportti

1/5-Vennystestiraportti-yhteenveto

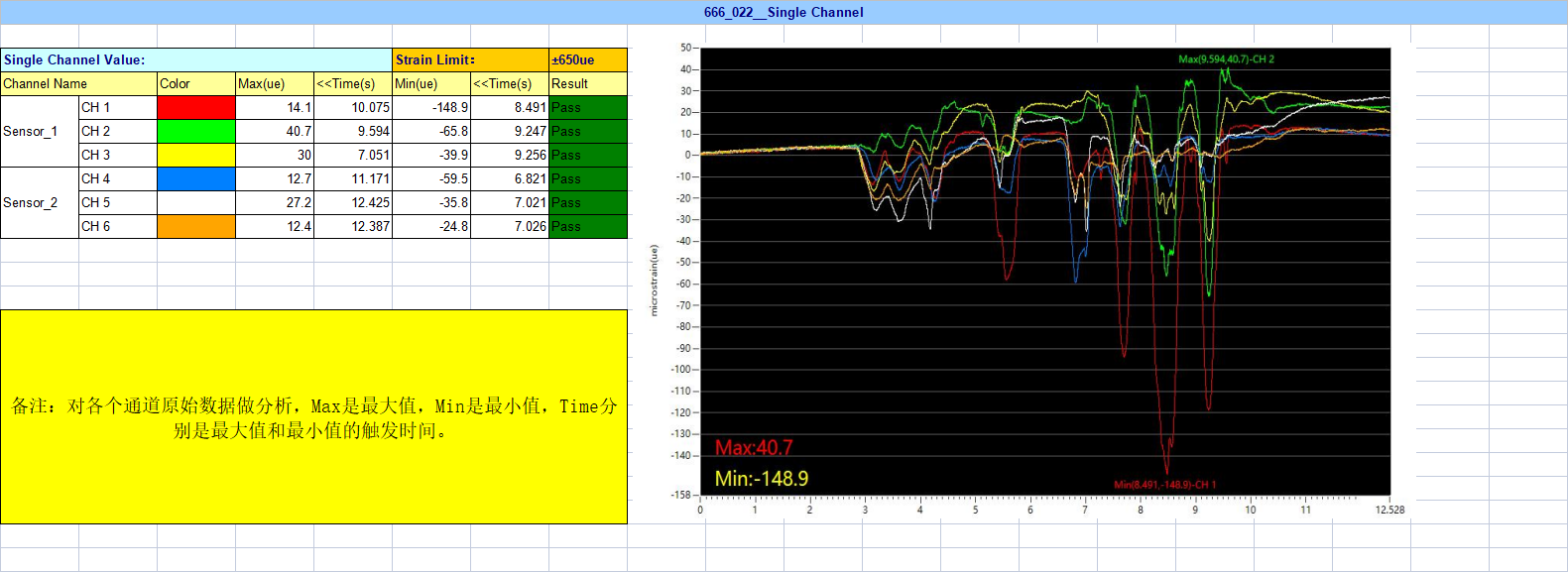

2/5 - Kantatestiraportti - Yksittäinen kanta

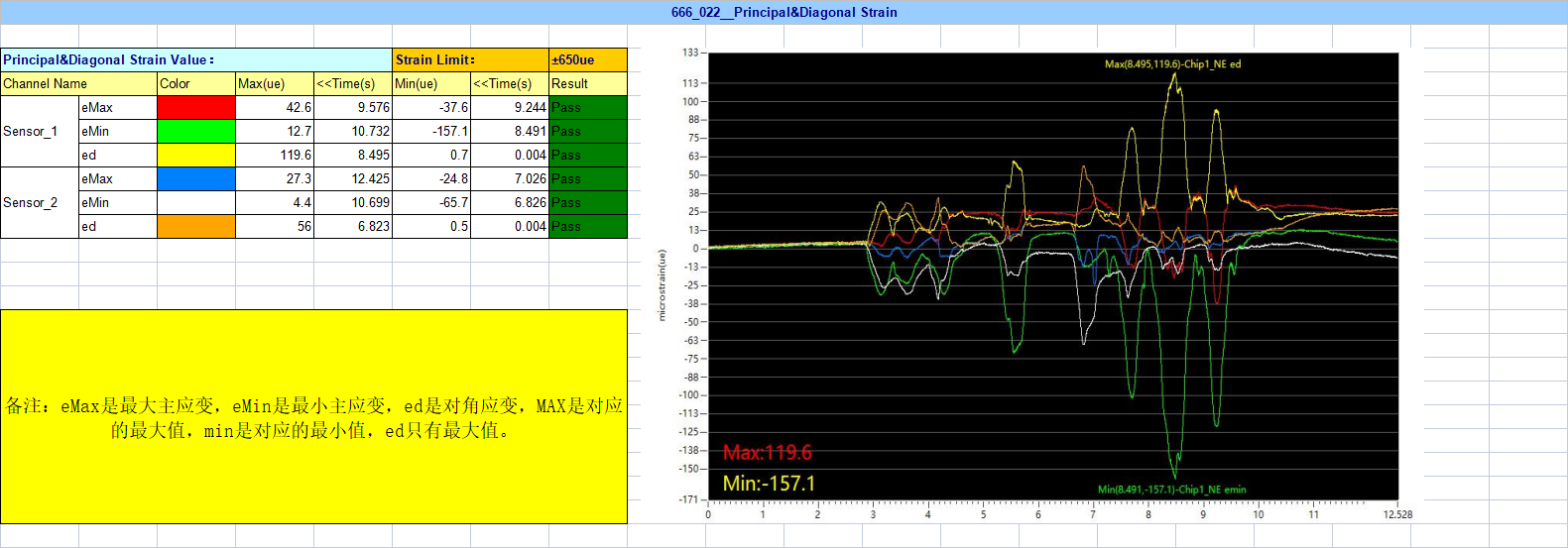

3/5 - Venymätestiraportti - P&D -kanta

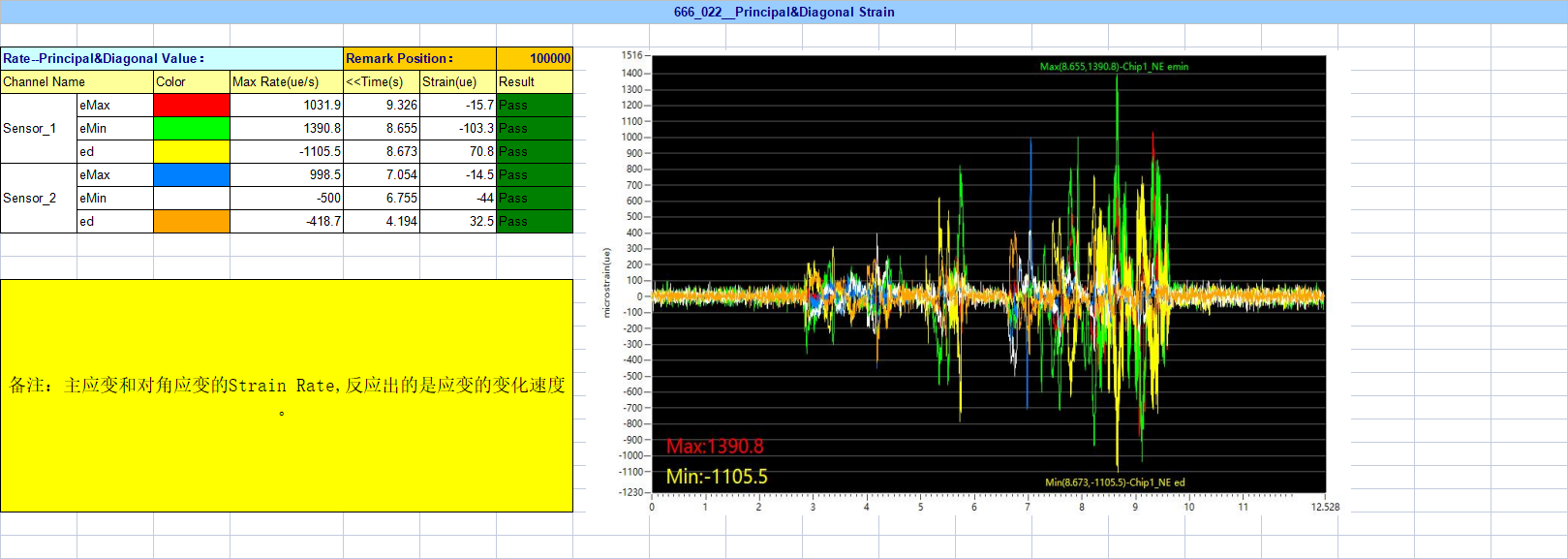

4/5 - Venymätestiraportti - Venymänopeus

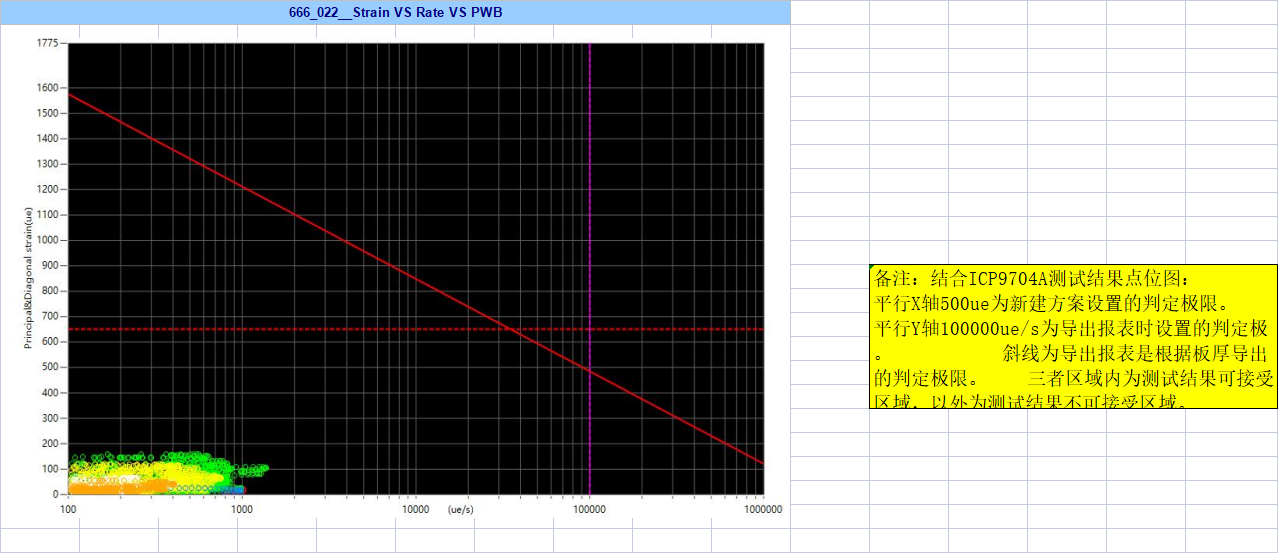

5/5-IPC-9704

✧ Käytä

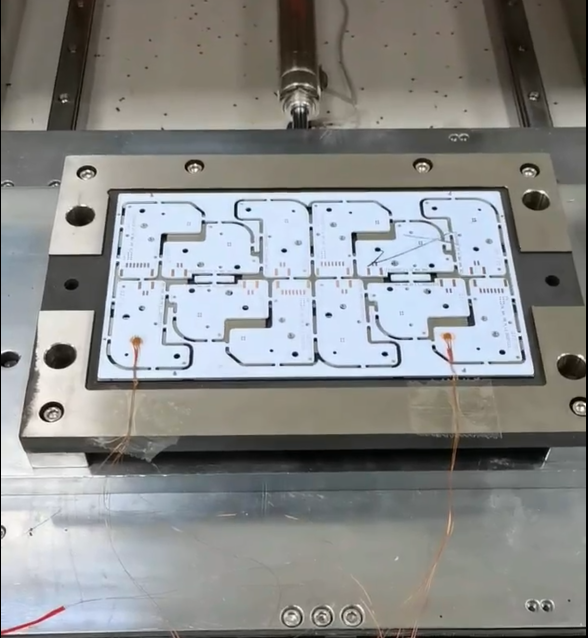

Sahanterän leikkauskoneen venytystesti

Monipyöräisen veitsileikkauskoneen rasituskoe

Lävistyskoneen jännitystesti

✧ Pakkaus ja toimitus

Puinen pakkaus

Puinen pakkaus

✧ Kuljetustie

→ Lentoteitse: näytteille ja pienille pakkauksille, kansainvälinen pikakuljetus, kuten DHL, UPS, EMS...

→ Meritse: suurelle paketille ja määrälle;

→ Muut tavat asiakkaan pyynnöstä.

Toimitusaika:

→ 35 päivän sisällä.

✧ Yrityksen tiedot

Vuonna 2008 perustettu Xiangjie Technology, jonka pääkonttori sijaitsee Dongguanissa, on maailman tuotantopääkaupunki.Se on piirilevyjen leikkaus- ja juotosratkaisuihin keskittyvä toimittaja, joka on sitoutunut tarjoamaan standardoituja korkealaatuisia laitteita ja räätälöityjä palveluita maailmanlaajuisille käyttäjille.Yli kymmenen vuoden innovaation ja kehityksen jälkeen, erityisesti piirilevyjen leikkaamisen alalla, Xiangjie Technologysta on tullut johtava SMT-oheislaitteiden valmistaja Kiinassa ja maailmankuulu valmistaja.Vahvan innovatiivisen T&K-tiimin ja vahvan myynti- ja huoltopalvelukyvyn ansiosta se on palvellut yli 30 maassa ja alueella.

✧ Näyttely

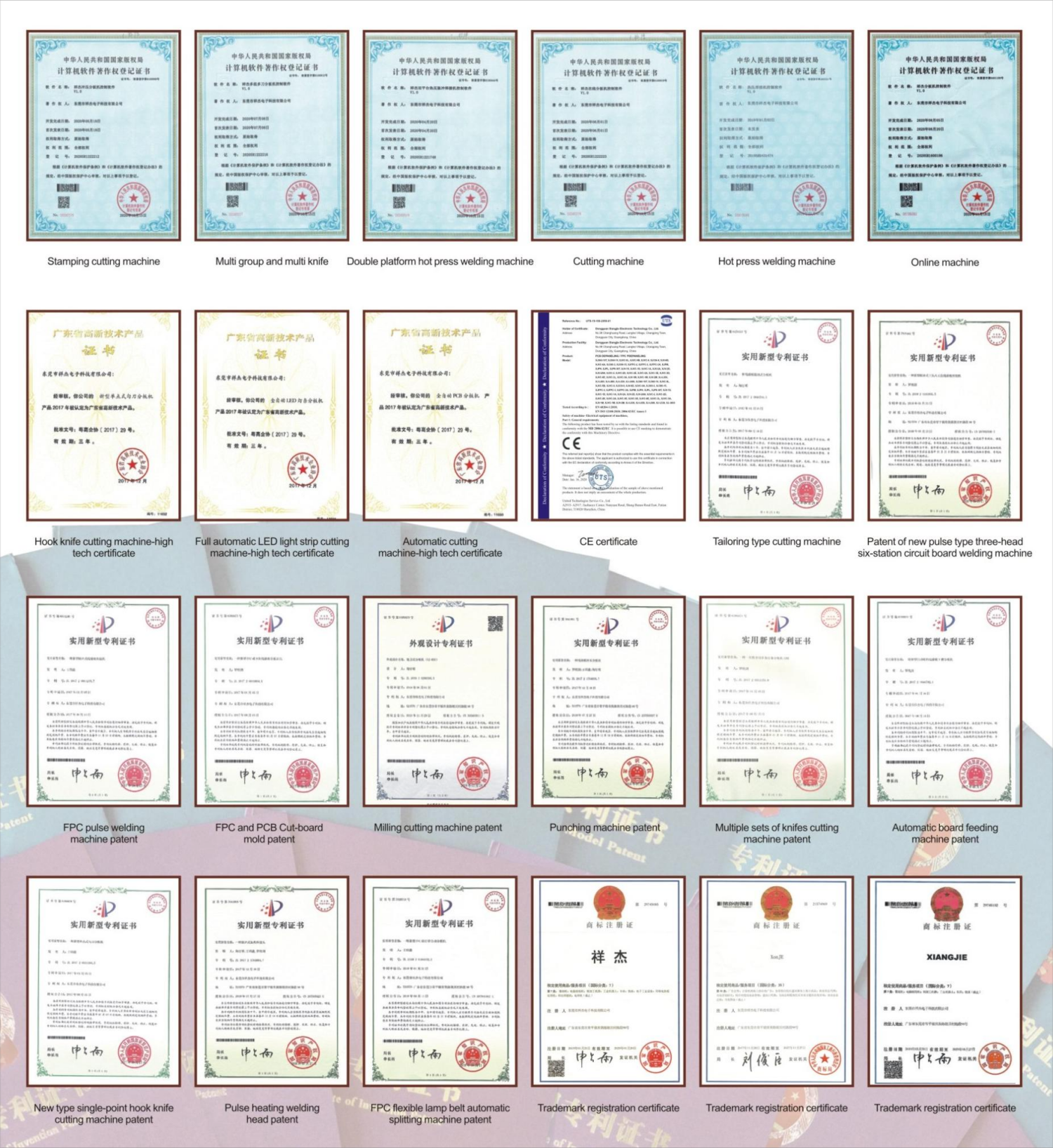

✧ Tavaramerkki ja patentti

Xiangjie Technology on saanut useita keksintöpatentteja, yli 30 käytännön patenttia ja erilaisia korkean teknologian tuotteita.

✧ UKK

K: Mitä voimme tehdä sinulle?

V: Ammattimainen SMT-oheislaitteiden toimittaja;Yli kymmenen vuoden kypsä alan kokemus

K: Oletko kauppayritys tai valmistaja?

V: Olemme valmistaja, jolla on täydelliset käsittelylaitteet

K: Mikä on toimituspäiväsi?

V: Noin 35 päivää maksun vastaanottamisesta.

K: Mitkä ovat maksuehtosi?

V: 100% saldo ennen lähetystä.

K: Mitkä ovat pääasiakkaasi?

V: PCB-kokoonpanon valmistaja, SMT-laitteiden valmistaja, valonauhan valmistaja jne.

K: Miksi valita sinut?

V: Johtava SMT-toimittaja Kiinassa;

Kaupan vakuutus USD 560 000+;Ammattimainen myynnin jälkeinen palveluryhmä.