Automaattinen sisään ja ulos pulssijuotoskone

✧ Ominaisuudet

1. Eri tuotteiden mukaan lämmitysnopeutta voidaan säätää.

2. Erikoismateriaalien hitsausliitokset varmistavat, että tuote on tasapainossa paineen alaisena.

3. Varustettu tyhjiötoiminnolla, on helpompi säätää kohdistusta.

4. Lämpötila on numeerisesti ohjattu, selkeä ja tarkka, kosketusnäytön toiminta, kiinalainen ja englanninkielinen näyttöliittymä, PLC-ohjaus, yksinkertainen käyttö.

5. Varustettu digitaalisella painemittarilla, painealue voidaan asettaa valmiiksi, ja käytetään SMC-tarkkuusohjainkisylinteriä, jolla on korkea paineen tarkkuus ja joka voi hitsata tuotteita, joiden juotosliitosväli on 0,5 mm.

6.Sopii kaikenlaiseen korkeatiheyksiseen TAB-, TCP-puristus- ja FPC-, FFC-, TFT- ja PCB-juotepuristusta varten.

*Juoteliitäntä FPC:n ja PCB:n ja liittimien välillä.

*ACF:n ja PCB:n välinen liitäntä ja liittimet.

*Liitä TAB:n ja PCB:n ja liittimien välillä.

*TFT:n ja PCB:n välinen liitäntä ja liittimet.

* Juotosliitäntä FFC:n (joustava litteä kaapeli) ja piirilevyn ja liittimien välillä.

*Juoteliitäntä seeprapaperin ja piirilevyn ja liittimen välillä.

*Juoteliitäntä erittäin hienon koaksiaalikaapelin ja piirilevyn ja liittimen välillä.

*Emaloitujen johtojen, kuten kiintolevyjen, juotosliitännät.vastukset, kondensaattorit, kelat, muuntajat, IC-kortit jne.

*Juoteliitäntä akun napakappaleen ja piirilevyn ja liittimen välillä.

*Pienten moottoreiden käämiliitäntöjen juotos.Hartsi lämpöpuristusliitos releille, tulostimille, laseille jne.

✧ Tekninen parametri

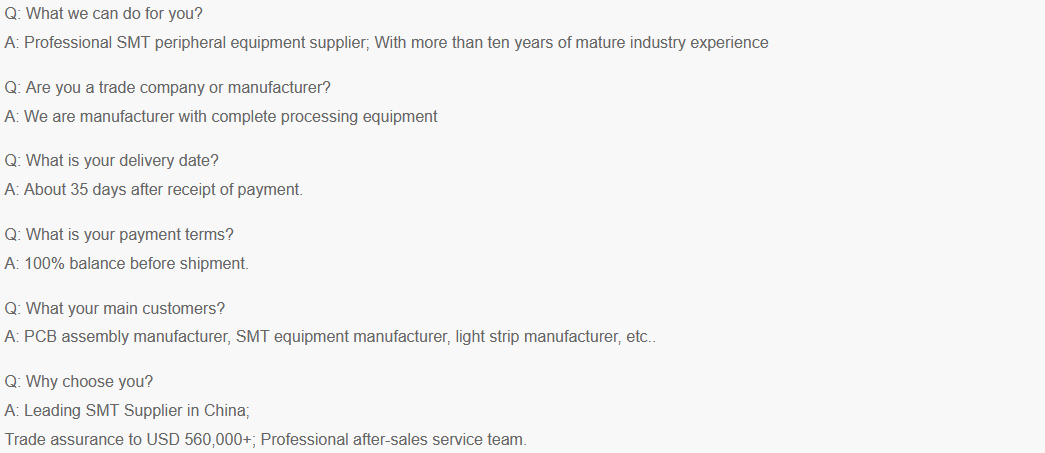

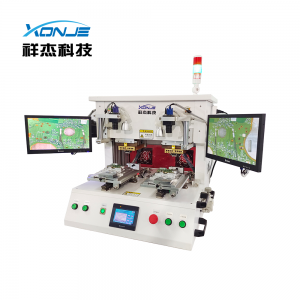

| Malli | XJPP-1A |

| Paikannusteline | 1 sarja |

| Työalue | 105*130mm |

| Käytä jännitettä | 220VAC 2,5kw |

| työpaine | 0,5-0,7 MPA |

| Koneen paino | 50kg |

| P*L*K | 490*600*720mm |

✧ Pakkaus ja toimitus

Puinen pakkaus

Puinen pakkaus

✧ Kuljetustie

→ Lentoteitse: näytteille ja pienille pakkauksille, kansainvälinen pikakuljetus, kuten DHL, UPS, EMS...

→ Meritse: suurelle paketille ja määrälle;

→ Muut tavat asiakkaan pyynnöstä.

Toimitusaika:

→ 35 päivän sisällä.

✧ Yrityksen tiedot

✧ Näyttely

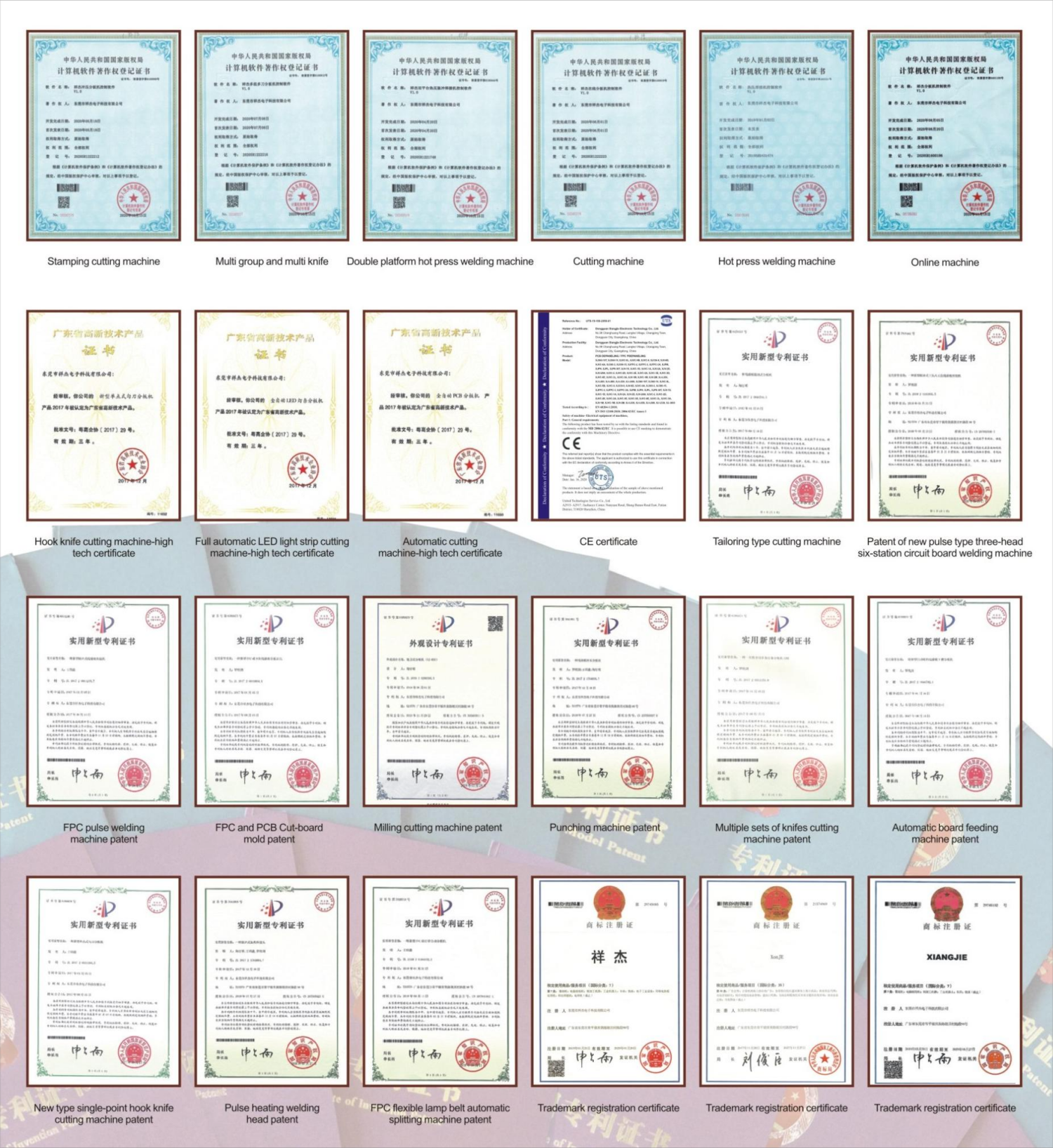

✧ Tavaramerkki ja patentti

Xiangjie Technology on saanut useita keksintöpatentteja, yli 30 käytännön patenttia ja erilaisia korkean teknologian tuotteita.

✧ UKK