Kaksiasemainen visuaalinen jyrsintäerotin

✧ Ominaisuudet

XJ-800-sarja käyttää pääasiassa jyrsimen nopeaa toimintaa, kaksialustaista neliakselista servokäyttöä monikytketyn piirilevyn erottamiseen esiohjelmoidun polun mukaan, korvaamalla manuaalisen katkaisun tai V-CUT- tai työntöleikkausvirheet, jännitys vaurioita, parantaa tuotteiden laatua ja vähentää romun määrää.Kone ottaa käyttöön ihmisen ja tietokoneen rajapinnan ja AC-servomoottorin.

WIN7-järjestelmän käyttöliittymä.Se käyttää korkean pikselin CCD-tuotantoohjelmaa leikkauspolun opettamiseen ja muokkaamiseen.Sitä voidaan muokata ja simuloida yhdessä vaiheessa.Se käyttää kahta servo-liikkuvaa alustaa.PCB-vaihtolaitteena ylä- ja alasubstraateille, se voi tehokkaasti lyhentää koneen joutoaikaa ja saavuttaa siten korkeamman tuotannon tehokkuuden ja laadun.Ohjelmistossa on MAKE-kompensaatio, sama työpenkkikopiointi, kaksoistyöpenkkikopiointi, varustettu isolla, keskikokoisella ja pienellä kolmella ikkunalla tarkempaa ohjelmointia varten, suorakaiteen muotoisen kehyksen lisääminen alkuperäisen kohteen perusteella, ohjelmointi on intuitiivisempaa ja tarkempaa ohjelmointia, MAKE geometrinen kohdistus kaapataan automaattisesti. Kaksi taulukkoa ovat täysin riippumattomia parametreista.Perinteiseen kolmiakseliseen koneeseen verrattuna vaste on nopeampi, parametrit ovat riippumattomia, tehokkuus on korkeampi ja leikkaustarkkuus on taattu.

✧ Tekninen parametri

| XJ-800 tekniset parametrit | XJ-800L tekniset parametrit | ||

| hanke | tekninen parametri | hanke | tekninen parametri |

| XYUZ-liikealue | 730mm*450mm*450mm*50mm | XYUZ-liikealue | 875mm*620mm*50mm*50mm |

| Yhden pöydän leikkausalue | 330mm * 360mm * 50mm | Yhden pöydän leikkausalue | 420mm * 520mm * 50mm |

| Lyijyruuvi / ohjauskisko | HIWIN ruuviohjain | Lyijyruuvi / ohjauskisko | HIWIN ruuviohjain |

| paikannustarkkuus | ±0.01 mm | paikannustarkkuus | ±0.01 mm |

| servojärjestelmä | Neliakselinen servomoottori | servojärjestelmä | Neliakselinen servomoottori |

| pääakseli | XONJE/ Kavos (valinnainen) | pääakseli | XONJE/ Kavos (valinnainen) |

| Karan taajuuden muunnos | Nopea taajuusmuuttaja | Karan taajuuden muunnos | Nopea taajuusmuuttaja |

| Karan nopeus | 2000rpm/min ~ 60000rpm/min | Karan nopeus | 2000rpm/min ~ 60000rpm/min |

| Karan työkalu | 0,8-3 mm | Karan työkalu | 0,8-3 mm |

| Hallitse isäntä | Teollinen tietokone | Hallitse isäntä | Teollinen tietokone |

| Leikkausnopeus | 1mm/sek ~ 100mm/s | Leikkausnopeus | 1mm/sek ~ 100mm/s |

| Leikkaustoiminto | Se voi leikata suoria linjoja, kaaria ja ympyröitä | Leikkaustoiminto | Se voi leikata suoria linjoja, kaaria ja ympyröitä |

| Sähköstaattinen käsittely | Sähköstaattinen eliminaattori | Sähköstaattinen käsittely | Sähköstaattinen eliminaattori |

| Pölynkeräystila | Valinnainen alempi pölynkeräys tai ylempi pölynkeräys | Pölynkeräystila | Valinnainen alempi pölynkeräys tai ylempi pölynkeräys |

| Koodin skannaus MES-toiminto | Tuki (valinnainen) | Koodin skannaus MES-toiminto | Tuki (valinnainen) |

| Pölynkerääjän koko | 1050mm * 800mm * 550mm | Pölynkerääjän koko | 1050mm * 800mm * 550mm |

| Virtalähde virta | Kolmivaiheinen viisijohdin 380v 3kw (mukaan lukien pölynkerääjä) | Virtalähde virta | Kolmivaiheinen viisijohdin 380v 3kw (mukaan lukien pölynkerääjä) |

| ilmanpaine | 5kg/cm2 | ilmanpaine | 5kg/cm2 |

| Koneen koko | 1270mm * 1200mm * 1850mm | Koneen koko | 1270mm * 1200mm * 1850mm |

| koneen paino | 680 kg | koneen paino | 700kg |

✧ Laitteiston esittely

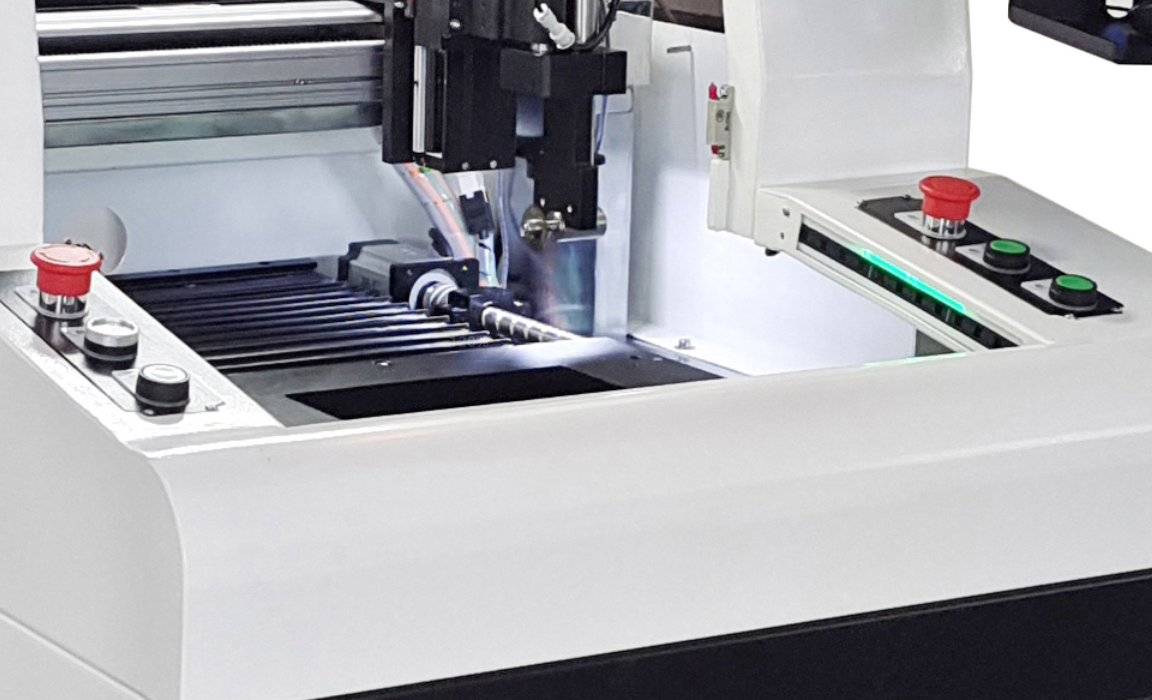

Nopea kara:

Tuodussa nopeassa karassa käytetään saksalaista SycoTec(Kavo) karamoottoria, jota käytetään laajalti alan huippuluokan halkaisukoneissa.Karalla on suuri nopeus (60 000 rpm/min), pitkä käyttöikä, kätevä kokoaminen ja purkaminen sekä sileä leikkauspinta ilman purseita ja vikoja.Se on myös varustettu alkuperäisellä SycoTec 4424 Spindle -taajuusmuuttajalla, jonka ansiosta karamoottorilla on pidempi käyttöikä, suurempi leikkausmomentti ja alhaisin lämpötilan nousuvaikutus.

Kaksoisservo:

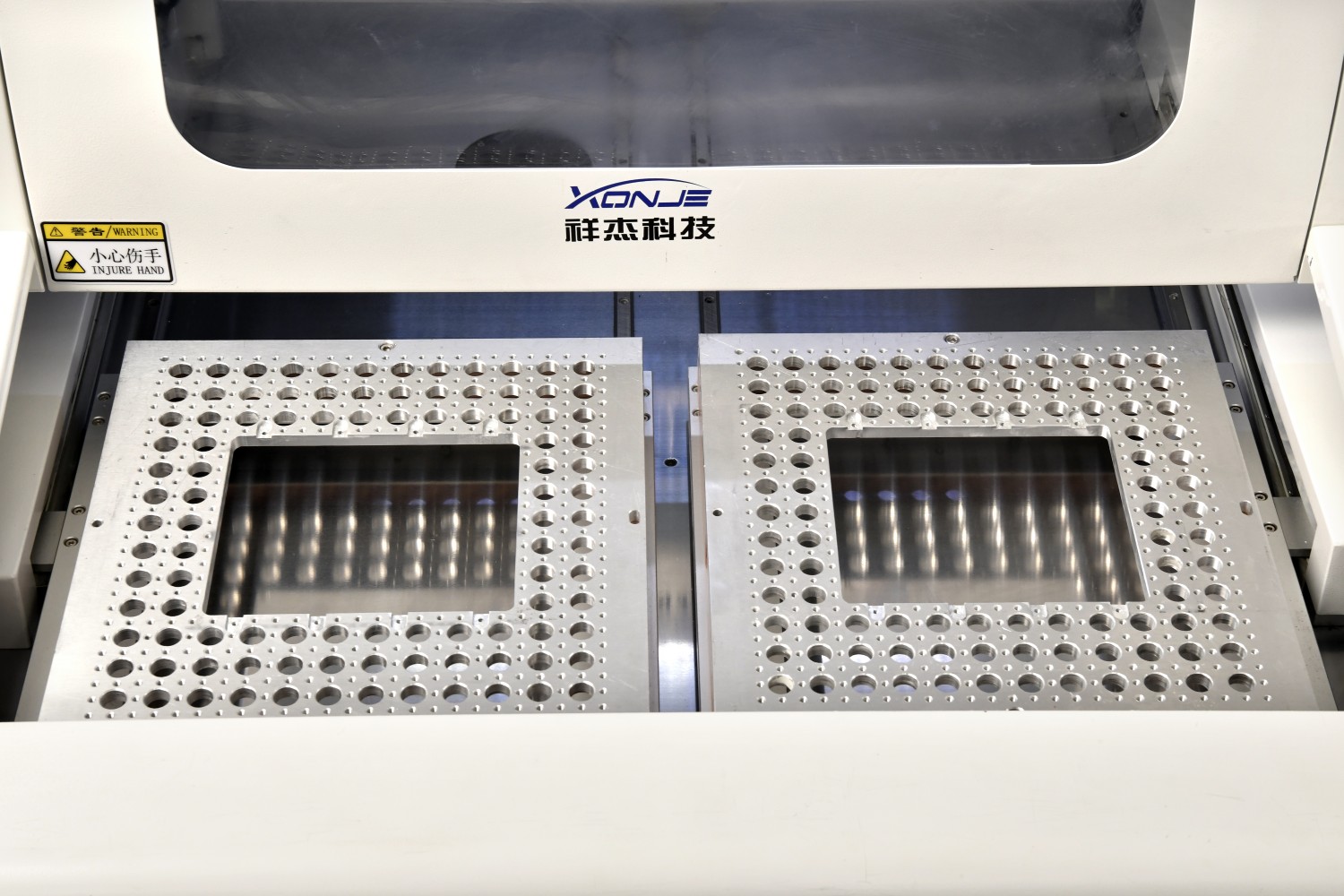

Servokäyttöistä kahta työtasoa käytetään vuorotellen prosessoimaan ja sijoittamaan piirilevysubstraatteja, lyhentämään odotusaikaa, lisäämään tuotantokapasiteettia ja ratkaisemaan sylinterikäyttöisen alustan tarkkuusongelmat.

Visuaalinen järjestelmä:

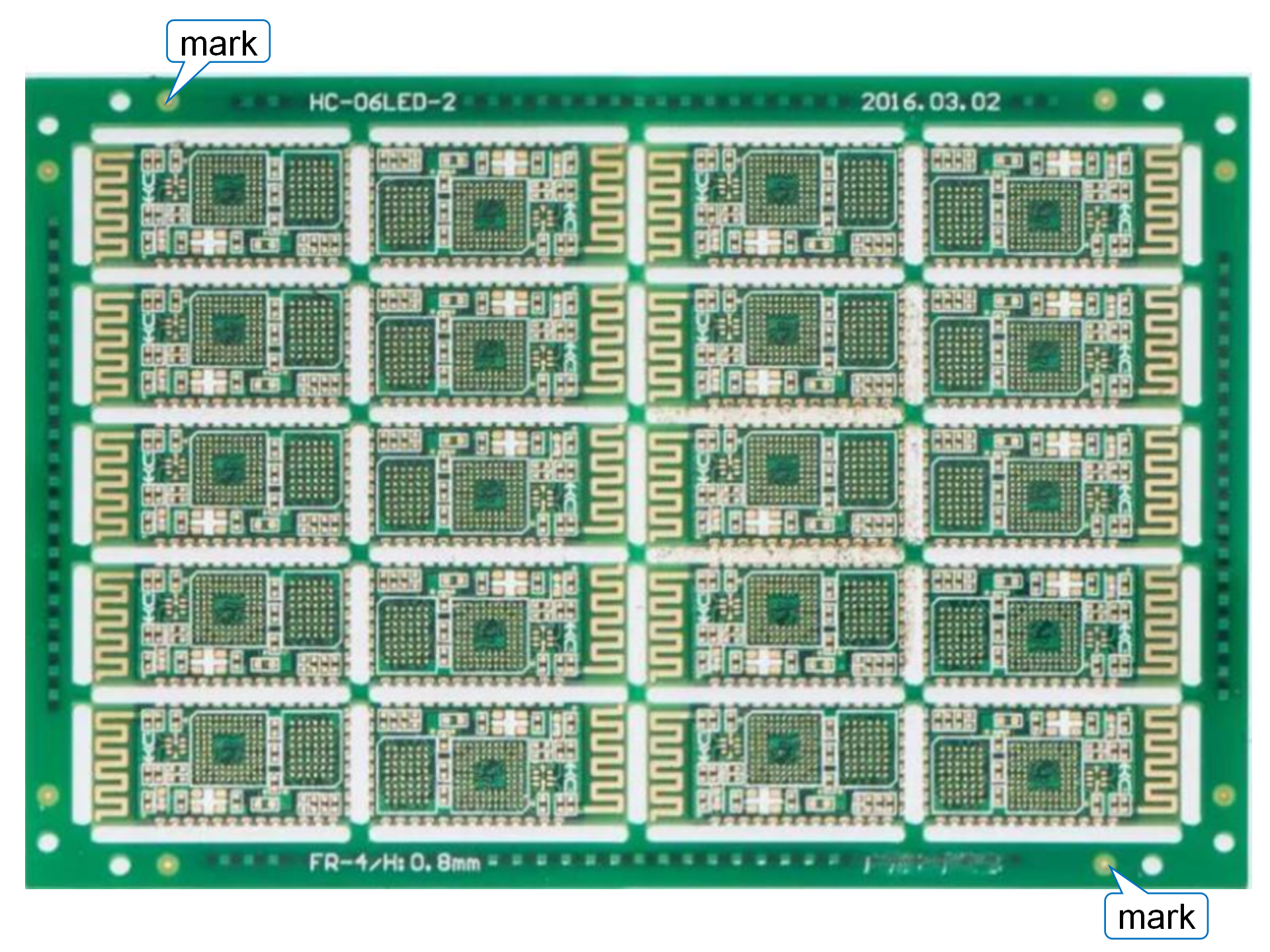

Korkean pikselin värillinen CCD ja suuri suurennoslinssi voivat auttaa ohjelman opetusta ja editointia simulointitoiminnoissa.Automaattinen MARK-asemointi- ja korjausjärjestelmä parantaa leikkaustarkkuutta ja estää lautaa vaurioitumasta, jos lauta ei ole paikallaan.On nopeampaa kopioida vasenta ja oikeaa ohjelmaa ja vaihtaa mallia.Valinnainen viivakoodin lukutoiminto 1D/2D-viivakoodin lukemiseen ja tallentamiseen tai lataamiseen, mikä on kätevä jäljitettävyyden ja digitaalisen hallinnan kannalta.

Tyhjiömenetelmä:

Ainutlaatuinen sisäänrakennettu pölynimuri, viidennen sukupolven muotoilu tekee laitteiden kokonaisvaikutelmasta kauniin ja tiiviin tilan, kaunistaa työpajan kokonaisvaikutusta, joustavaa liikkuvuutta, kätevää sijoitusta ja huoltoa.Lyhennä tyhjiöpolkua ja paranna alipainevaikutusta hyvällä ilmatiiviydellä ja hiljaisella äänellä.Pölypussi voidaan puhdistaa ja käyttää uudelleen, mikä vähentää tuotantokustannuksia!

Turvavaloverho:

Alkuperäinen japanilainen KEYENCE-turvaritilä on valittu suojaamaan käyttäjien käyttöturvallisuutta ja välttämään onnettomuuksia.

✧ Visuaalinen järjestelmä

Korkean pikselin värikamera ja suuri suurennoslinssi voivat auttaa ohjelman opetus- ja editointisimulaatiotoimintoja.Automaattinen MARK-paikannuskorjausjärjestelmä.

Merkintäpisteen korjausperiaate

Piirilevyn merkintäpisteen ja leikattavan liitoskohdan sijainti on fyysisesti kiinteä.Leikkauspolkua muokatessa, merkintäpisteen määrittämisen jälkeen muokattu leikkausrata sidotaan merkintäpisteen suhteelliseen sijaintiin.Kun piirilevy on esijännitetty, merkkipisteen sijainti muuttuu piirilevyn mukana.Kun kamera skannaa merkkikohtaa, se laskee automaattisesti siirtymän ja kompensoi sen sitten leikkausradalla.

✧ Pakkaus ja toimitus

Puinen pakkaus

Puinen pakkaus

✧ Kuljetustie

→ Lentoteitse: näytteille ja pienille pakkauksille, kansainvälinen pikakuljetus, kuten DHL, UPS, EMS...

→ Meritse: suurelle paketille ja määrälle;

→ Muut tavat asiakkaan pyynnöstä.

Toimitusaika:

→ 35 päivän sisällä.

✧ Yrityksen tiedot

Vuonna 2008 perustettu Xiangjie Technology, jonka pääkonttori sijaitsee Dongguanissa, on maailman tuotantopääkaupunki.Se on piirilevyjen leikkaus- ja juotosratkaisuihin keskittyvä toimittaja, joka on sitoutunut tarjoamaan standardoituja korkealaatuisia laitteita ja räätälöityjä palveluita maailmanlaajuisille käyttäjille.Yli kymmenen vuoden innovaation ja kehityksen jälkeen, erityisesti piirilevyjen leikkaamisen alalla, Xiangjie Technologysta on tullut johtava SMT-oheislaitteiden valmistaja Kiinassa ja maailmankuulu valmistaja.Vahvan innovatiivisen T&K-tiimin ja vahvan myynti- ja huoltopalvelukyvyn ansiosta se on palvellut yli 30 maassa ja alueella.

✧ Näyttely

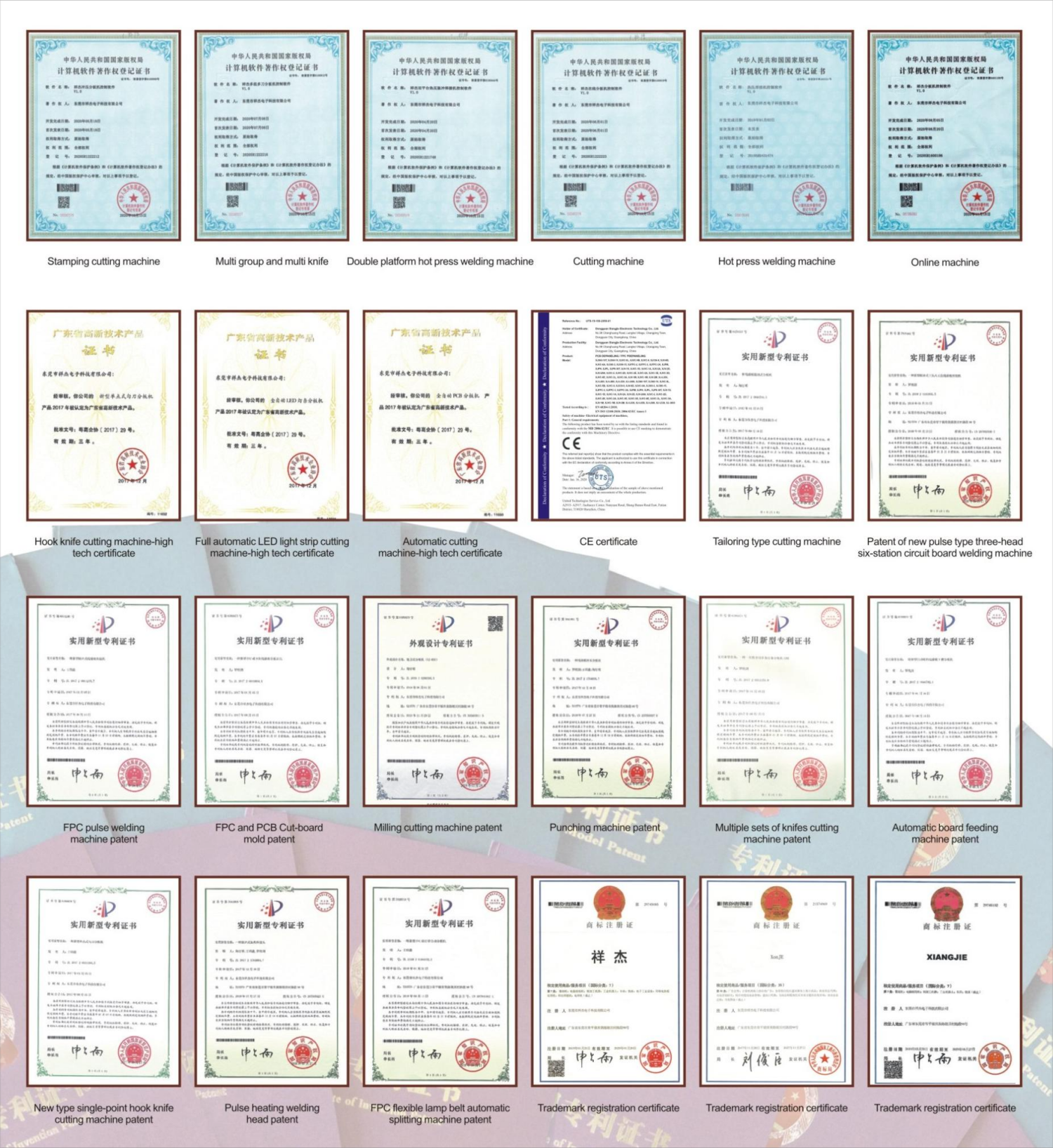

✧ Tavaramerkki ja patentti

Xiangjie Technology on saanut useita keksintöpatentteja, yli 30 käytännön patenttia ja erilaisia korkean teknologian tuotteita.

✧ UKK

K: Mitä voimme tehdä sinulle?

V: Ammattimainen SMT-oheislaitteiden toimittaja;Yli kymmenen vuoden kypsä alan kokemus

K: Oletko kauppayritys tai valmistaja?

V: Olemme valmistaja, jolla on täydelliset käsittelylaitteet

K: Mikä on toimituspäiväsi?

V: Noin 35 päivää maksun vastaanottamisesta.

K: Mitkä ovat maksuehtosi?

V: 100% saldo ennen lähetystä.

K: Mitkä ovat pääasiakkaasi?

V: PCB-kokoonpanon valmistaja, SMT-laitteiden valmistaja, valonauhan valmistaja jne.

K: Miksi valita sinut?

V: Johtava SMT-toimittaja Kiinassa;

Kaupan vakuutus USD 560 000+;Ammattimainen myynnin jälkeinen palveluryhmä.